(30 December, 2003)

This is a followon to the page in which I describe my effort to resuscitate a rather dead nitrogen laser that we acquired on eBay a while ago.

I recently brought up a commercial dye laser (also found on

eBay), and discovered that although it is a fine device,

there are some limitations to what I can run through it. It

isn’t particularly suitable for some of the dyes I’d like to

test, so I’ve returned to the Avco head, to see whether I

can bring it back on line.

It has been some time since I worked on this laser. In the interim I’ve done various other things, and I’ve been cooking the nitrogen laser issues on the back burner. Several things have emerged; some of them are developed here. (I’m also working on another design, not a commercial head but a build-from-scratch, which I’ll document elsewhere.)

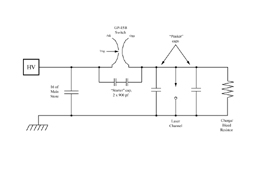

I’ve decided to make a change in the circuit topology:

This puts the switch directly on the laser channel. (The original topology had the main store mounted on the channel, and the switch mounted on the main store. See the previous page for details.) The main store, btw, is actually ~16 nf; I’ll fix the diagram when I have time.

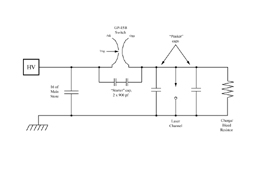

The advantage of mounting the switch on the channel is twofold: first, it means that the switch and cap won’t necessarily stick out as far from the backplate. Not only is that handy in terms of positioning the laser, but it probably reduces the inductances involved. Second, it lets me use "doorknob" capacitors as the main store or "dumper" cap. Here are eight doorknobs, each 2 nf, mounted on the backplate:

I was fortunate enough to have caps with broad, low-inductance terminations, though there’s a fair chance that the more usual narrow connections would have worked almost as well.

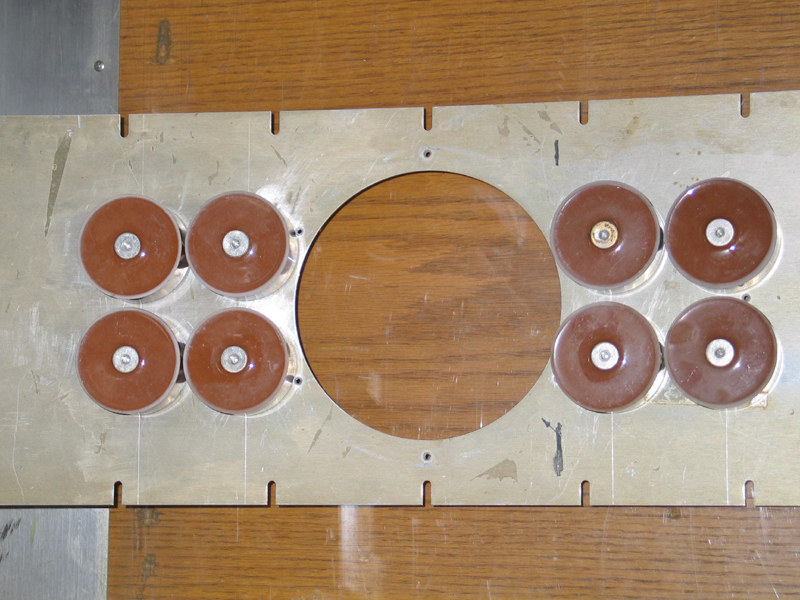

Here is a detail of the assembly, with caps and switch in place:

You can see the transparent file folders that I’m using as insulators (hey, they were available), and the two large white wires that go off to the trigger unit. (Very lovely 60-kV-rated wire.)

I will be putting a vacuum regulator on this head, so that I can adjust the pressure. If I presume, for simplicity, that it will perform optimally at 100 V / Torr cm, and if I figure that the channel width is 4 cm (see next photos), I need 4 kV on the channel at 10 Torr, and 8 kV at 20 Torr. Unless I’m charging the "peaker" caps extremely rapidly, I doubt that I can get much more than 8 or maybe 12 kV across it, so I need 20-30 Torr. The vacuum regulator goes down to 10 Torr, which is just fine.

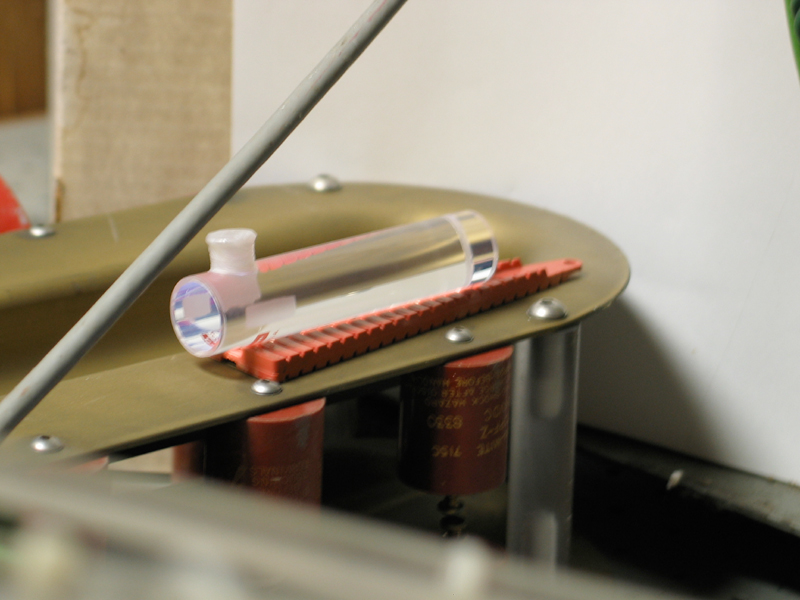

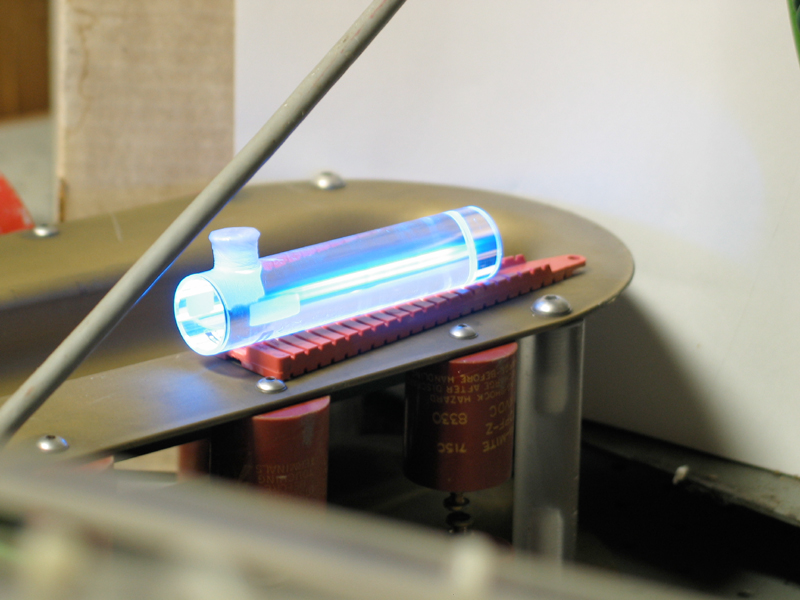

I’ll report results on that when they become available; in the meanwhile, here’s a cell full of 7-Diethylamino-4-Methyl-Coumarin, first by roomlight and then caught with a pulse going into it:

(My apologies for the quality of the pictures -- it was fairly late, and I was holding the camera with one hand and the trigger switch with the other. I’ll provide better images later on.)

Note, added in proof, 2004 February 03:

Here are some photos that show a dye laser that I’m

pumping with this head, and a photographic tuning curve

for Rhodamine 6G.

(2004 February 03)

It eventually occurred to me that I had made

a significant error when I rebuilt the laser.

To wit, I was putting positive HV on the cathode.

Nitrogen lasers being what they are, it ran; but

I suspected that I could get better results with

the correct polarity, so I decided to swap it

around.

At about that same point, however, I was having

a certain amount of trouble getting the spark

gap to trigger, and I also managed to lose one of

the 2-nf dumper caps. (The cracks are not huge, but

they are clearly visible in the larger version of

the picture.)

I changed out the GP-15 for

a more recent GP-15B while I was replacing the cap,

thinking that perhaps the GP-15 was nearing the

end of its useful lifetime. Alas, although the newer

gap triggered nicely at first (at least with the

power supply "backwards"), when I corrected the

polarity I was unable to get it to trigger. At all.

I then spent quite some time investigating our

trigger units (one TM-11, old style, and three

of the newer TM-11A design). I’m still not entirely

certain about the issues, but I have decided to

rebuild the laser again, and I’m revising the

topology back to what it was originally. I was

going to insist on operating the gap in what the

literature on it describes as "Mode A", in which

the trigger pin and the "adjacent" electrode (the

one that surrounds it) are positive, but that

would have involved a certain amount of hanky-panky

because the end of the gap with the trigger electrode

would have been at 30 kV, face down (as it were),

with the trigger electrode inside the capacitor

bank.

Milan Karakas has convinced me to try, instead,

triggering in "Mode B", in which both the trigger

pin and the "adjacent" electrode are negative. This

puts the trigger electrode facing out, which is

much more convenient, and allows me to maintain

this area at or near ground potential except during

firing, so I won’t need any isolation between the

TM-11A and the switch. Here’s a revised schematic;

sorry it’s a bit rough.

Here are some photos that I took today, showing

intermediate stages in the rebuild. The first two

show the baseplate of the new assembly, which

attaches to the cathode rail. Sorry they’re a bit

blurry. The next two show the rail itself, at the

attachment point, without and then with the protective

insulator.

The next two show one of the capacitors; they are

not quite as nice as the 2-nf ones I was using

previously: the termination is considerably narrower,

which means that it has higher inductance. At these

speeds, that’s a big issue, and I’ve been reluctant

to use these at all. I noticed, however, that if I

clean any excess epoxy off the shoulder, they are at

least half as wide as the really good ones, and

should do; a washer allows me to make good contact.

I’ve already shown the baseplate; here’s the rest of

the assembly, as it went together. I’ve included my

hand in one of them, to give you a sense of scale.

The last of these shows the finished assembly, with

one of its insulating plastic sheets (actually half

a dozen thicknesses) in place. Another sheet goes

under the baseplate (actually at the top in that

photo, because the assembly is upside-down), to keep

it from shorting to the box during firing. More plastic

will go into place during assembly, because a sheet of

copper or brass shim stock will connect the top of the

spark gap to the box, and it passes much too close to

the upper plate of the capacitor bank for comfort at

30,000 volts.

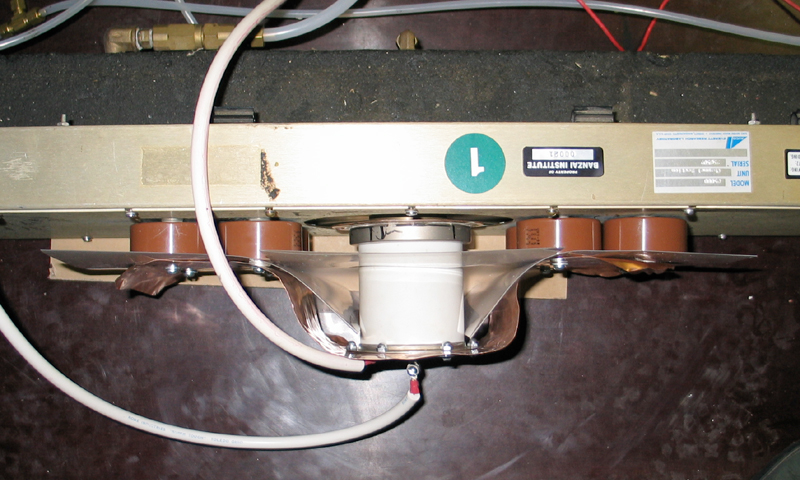

Here it is with everything in place, actually on

the C5000 head:

The two small brown doorknob capacitors standing in front

of the spark gap are there to get it to start quickly when

it triggers. The manufacturer recommends pushing at least

10 amps through it to get it to form a conduction channel;

450 pf at 30 kV should push over a hundred amps, and

should wake it right up.

Before I could try this setup, I had to add some

insulation. Either I didn’t add enough, or there was some

sort of surface spark, because when I raised the voltage

to the highest level I ordinarily use, there was a

flashover. (I was unable to get the spark gap to trigger

at any voltage I was able to reach, unfortunately.)

It’s now too late at night for me to continue working on

anything with 30,000 volts all over it, so I’ve shut the

system down. I’ll go back tomorrow and see what happened

and what I think I should do about it. (One thing I may do

is build a trigger unit that puts out a bit more

voltage. I think my TM-11 boxes are getting old.)

(26 February, 2004)

I now have a homebrew trigger unit that

runs a GP-14 well

at relatively high voltages (the 14 is rated for 12 to 24

kV in air), but not near the bottom of its range. It does

not run the GP-15B yet, but I’m working on improvements,

and I’ll post more to this page as it happens, or to

the next page — I’ve decided to rebuild yet again.

To the top of the LASERs section

Email: it’s the usual “a@b.com”, where

you can replace A by my first name (jon, only 3 letters,

no “h”), and B by joss.

Phone: +1 240 604 4495.

Last modified: Fri Jun 14 23:06:09 EDT 2013

Trouble in the Works

Some Weeks Later...

The Joss Research Institute

19 Main St.

Laurel MD 20707-4303 USA

Contact Information: