This page presents the design and construction of a nitrogen laser that can be built by a Do-It-Yourselfer. It is a scaled-up version of a smaller and simpler previous design.

The laser is constructed, as much as possible, from materials that are available at hardware stores and hobby shops: plastic “lumber”, aluminum rulers, steel rods, compression fittings, pieces of basswood and spruce, etc. I used a commercial spark gap, but it is eminently feasible to build one. The two items used in this design that are not easy for a do-it-yourselfer to construct are the “doorknob” capacitors, which are available from time to time on eBay; and the fused silica windows, likewise an eBay item, though it is possible to use fused silica microscope slides, which I buy from EMS.

This laser uses either nitrogen or a mixture of nitrogen and helium at low pressure (roughly 30-90 Torr each), runs at 25-30 kV, and puts out pulses of more than 1.6 millijoules, lasting ~8 nsec FWHM. This corresponds to average pulse power of 160 kW and (assuming a vaguely sinusoidal pulse shape) peak power of roughly 230 kW. It is enough power to make small sparks if you focus the beam onto a metal surface:

[For anyone who is reading this before the prototype is

completed & tested, those numbers are placeholders

that I have achieved with the prototype, and will be

replaced by higher numbers when I get the prototype

optimized better.]

Construction and operation of this laser (or any

high-performance pulsed laser, particularly one that

emits output that is invisible) should be attempted only

by people who have been trained to handle lasers and

high voltages. The term “training” includes

relevant and appropriate DIY experience; but if you have

never built a working nitrogen or TEA CO2

laser before, this is not the right place to start. Even

the previous design, referred to above, is a bit difficult

for a beginner.

(30 July, 2005; 4 August, 2005; 7 October, 2005;

May and June and September, 2006; October 2009.)

This laser is intended to operate at reduced pressure,

though there is some chance that it will work with a

full atmosphere of helium inside the head. The channel

is roughly 3 mm deep (the actual depth depends on

discharge parameters, as well as the width of the

electrodes) and about 22 mm wide. It has active length

of about 600 mm, but the electrodes are about 914 mm

long (this may help to reduce the amount of sparking at

the electrode ends). The overall length of the head is

approximately 950 mm.

The switch is an EG&G GP-32B spark gap, which is

rated up to at least 30 kV in air. Although such gaps

are available on eBay from time to time, it is eminently

possible to construct your own triggered spark gap if

you cannot buy one or even simply prefer not to. I must,

however, stress the fact that a triggered gap with low

inductance is almost certainly required for good

performance. Any gap with excessive inductance is (in

the words of an earlier era) unlikely to give

satisfaction.

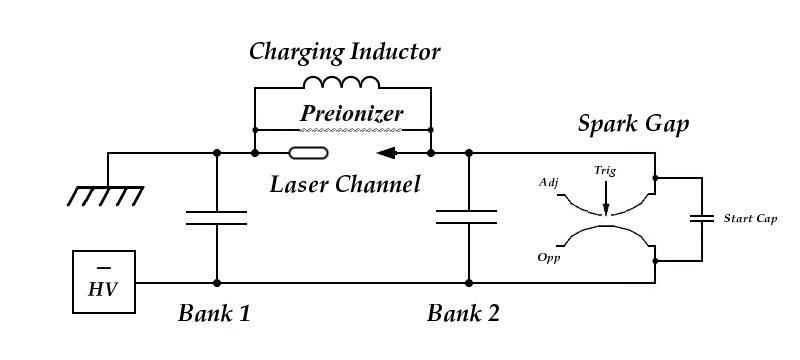

Here is the schematic diagram of the laser:

The preionizer is a coating of 100-mesh silicon carbide powder

embedded in a thin layer of epoxy on the inner surface of the

upper sidewall of the head. It is connected to the electrodes

by steel rods that also serve to space the upper sidewall

away from the electrodes. I have indicated a charging inductor

here, but you may find that a resistor works better; it is a

good idea to try it both ways.

Here are some of the things you will need if you want

to build this laser:

(Two aluminum rulers, 1/8" thick and at least 35" long;

two wooden yardsticks, about an inch and a half wide;

two pieces of spruce from the hobby shop, 3/16" square;

two more pieces of spruce, either 1/4" square or, if you

can’t find that size, 1/4" x 3/8" or even 1/4" x

1/2"; one or more tubes of silicone rubber caulk. I have

found that the “XST” paintable version,

shown in the photo, works better for me than other

versions I’ve tried.)

In addition to what you can see here, you will need a

brass kickplate from the hardware store (I used a large

one, 8" x 34"); 16 laser-grade “doorknob”

capacitors (I used capacitors rated 2000 pf and 40 kV);

some sort of spark gap switch and a trigger circuit to

operate it (I used an EG&G/PerkinElmer GP-32B, which I

got on eBay, but you can certainly make your own gap);

some plastic quick-connects for gas and vacuum (you can

use metal fittings if you can’t find plastic

ones); a pair of fused silica windows; a mirror; some

silicon carbide grit to make a preionizer (unless you

decide to build a more traditional preionizer, a subject

I will try to discuss later, or you can email me if you

have questions); various nuts and bolts; one or two

types of epoxy cement; and a certain amount of

high-voltage insulating varnish. Also, of course,

various hand tools, preferably including a

jeweler’s saw, a high-speed rotary tool, a set of

small files, an X-Acto™ knife or equivalent, and

so on.

Oh, yes: you will also need a high voltage power supply

and a vacuum pump of some sort, if you actually expect

to operate the laser.

Notice that the electrodes are aluminum rulers, which

will be cut down from their original 48" length to

35". These provide both good stiffness and a clean

straight edge, though you have to choose them with

some care — I have seen many bent rulers at

hardware stores during the development of this design.

Even if you choose them well, they may not provide the

optimum edge profile; different researchers have

obtained varying results that seem to depend on obscure

details of design, and it is very difficult to predict

in advance what the optimum edge shape will be. In any

case, it turns out to be important to remove the

anodizing (or paint) from the working edge. Anodizing

creates a tough surface coating, which is difficult to

remove; if you scratch up the edge in the process of

getting it off, you will probably want to polish it

smooth again. You can run through increasingly fine

sandpaper until you get to at least 1,000 grit, which is

available at auto-parts stores, or you can get up to 600

or 800 grit and then either stay with a satin finish, or

rub with fine steel wool. You will need to sand again if

you scratch the edge up in the process of removing

paint or rounding the corners.

You will also have to remove the paint or anodizing at

the places where the ruler makes contact with the

doorknob capacitors. I used a handheld rotary tool

(there are several common brands, all of which can

rotate quite quickly) with a wire brush wheel. This is

fine for the capacitor contact areas, but I am worried

that it may be too uneven for the edges, so I

didn’t use it there (see photo, when I get a

chance to post it). The paint on these rulers, btw, was

so thick that making the one pair of electrodes used up

the wire brush wheel, and I will have to get another

one.

It is crucially important that you make sure there are

no gaps in whatever sealant you use to attach the

electrodes to the spacers, and the spacers to the

sidewalls. It is impressively difficult to find and seal

all of the leaks in a new head, and sealant gaps just

make things worse. When you have assembled the head, you

should test for vacuum leaks (and fix them, and retest)

before you connect it to the capacitors on the

baseplate — it is a lot easier to reach the

underside with the head unattached. After you have made

sure it is sealed, if you intend to operate the laser at

voltages above about 20 kV, you need to paint

high-voltage insulating varnish on the baseplate

(visible in the photo that I will add when I get a

chance) and on the undersides of the electrodes, to

prevent flashovers. Remember to avoid insulating the

areas where capacitors will be attached (!).

Test the head again after you insulate it and attach it

to the baseplate, as the stresses involved could open

old leaks or create new ones.

Because nitrogen lasers need to be fast (see

my page about the issues involved

if you want more information about this), you should use

broad foils to connect the cathode and the baseplate to

the spark gap switch. It is best to cover the full width

of the doorknob array, but I found that I could get away

with 12" and still achieve reasonable performance. The

switch itself should have the lowest possible inductance,

which means that it should have wide electrodes. I use

commercial spark gaps for convenience, typically EG&G

GP-15B for voltages of at least 25 kV, GP-32B for

voltages of about 15-30 kV, and GP-14B for voltages of

12-24 kV. For smaller lasers, GP-70 gaps are suitable for

12-24 kV. These gaps are currently manufactured by

Perkin-Elmer, and may be sold as either EG&G or PE.

My prototype of this laser used a GP-32B.

Here are some photos of my prototype head, first parts

during construction and then discharge examples. These

are not the least bit optimized, and the examples are

not photos of the final version; my apologies.

Here is a view of the discharge in the prototype,

before I changed from a glass “roof”

to a wooden one:

Here is a view of the laser pumping a small dye laser,

using a homemade cuvette:

(Again, this is an earlier version of the prototype,

with considerably less output power than the final

one. Even so, it had no trouble pumping the dye.)

(19 September, 2006)

CAUTION

General Plan

Materials and Construction

Views

Initial Testing