[Started on April 8, 2011.]

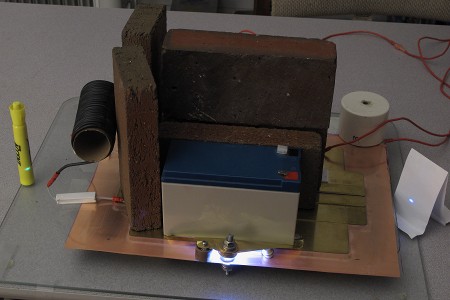

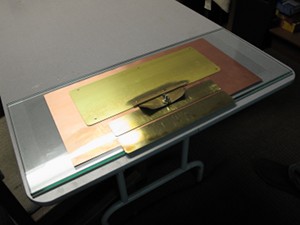

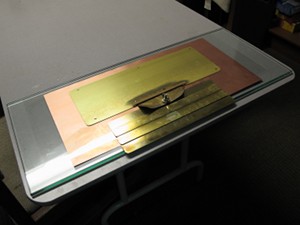

This photo shows a version of the laser in operation.

The output is not visible to the eye; the fluorescent

objects on the left and right indicate the presence of

the beams. (Because there are no mirrors, the laser

produces two.)

Amateurs have been building lasers since fairly shortly after the laser was invented. Several laser projects even appeared in the late (and much lamented) Amateur Scientist column in Scientific American, which is now, fortunately, available in its entirety on CD-ROM. There are also various pages on the Web that provide information about DIY lasers of various sorts, and I provide links to some of them at the end of this page.

Unfortunately, I see quite a few videos on YouTube in which someone has bought a little laser module and hooked it up to a battery; they then proudly claim that they have built a laser. That’s pretty sad, especially when almost any of them actually could have built a laser. This page is for you if you really want to build a laser, and not just buy one.

The lasers I describe here are TEA nitrogen lasers. (TEA stands for Transversely Excited, Atmospheric [pressure].) That is, they do not involve either vacuum or compression. The basic design is sufficiently straightforward that it can be built by a high school student who is particularly interested, or possibly even a middle school student who is truly determined. A laser of this type that is constructed with some care and is properly adjusted should put out more than enough power to drive a small dye laser, as you can see in the addendum near the end of the page. There is also an upgrade path, which can become quite challenging.

Before we get any further along, we need some safety

information and a disclaimer.

These lasers use high voltages, and capacitors that can store lethal amounts of energy. They put out invisible ultraviolet light that can damage your eyes and skin. It is extremely important to take adequate safety precautions and use appropriate safety equipment with any laser; and it is crucially important with lasers that involve high voltages and/or produce invisible beams!

In addition, these designs use open spark gaps, which will damage your hearing if you do not use adequate ear protection. I strongly suggest that you acquire and use at least a pair of sound-protection earmuffs of the type used by shooters at rifle and pistol ranges; they look about like this:

(These cost me $35, and they are definitely worth it.)

Earplugs can also help, but by themselves are probably not sufficient unless they decrease the volume by about 33 db and you put them in correctly; I suspect that only special ones that are made to fit your own ears are really good enough.

If you are not using enough hearing protection, you will

probably get a nasty headache if you run the laser for a

while. Take that as a warning, and get better protection!

You can make a new spark gap, and you can make a new

laser; but you cannot make new eyes, ears, or fingers.

In the process of working up this page I built several versions of the laser, increasing the complexity each time I revised it. Here (Video 1a) is an informal video that begins with a simple laser, similar to the first version I present on this page, though with a different spark gap design. The laser was not very sophisticated, but as you can see in the video, it worked. (In retrospect, though, I will point out that in the later part of the video it is firing too often.) Here (Video 1b) is a video in which I assemble and operate a somewhat more sophisticated version. [Note, I did not compress this video, and the filesize is >40 MB.]

It is important to note two things about this. The first is that building a simple machine provides you with experience that helps you build more advanced versions. (No surprise there, I trust.)

The second is that this first simple machine can easily evolve, in stages, into a considerably more advanced laser with far better performance. You don’t have to throw it away and start again from scratch, because you can create a more advanced version by modifying it, as I do in the course of the first video.

Of course, if you want to start over again, nothing prevents you from doing so. The version that you see in (for example) Figures 22 and 23 was a complete rebuild, as is the one in Video 1b. That’s another handy thing about these lasers: after you have built several, you will probably find that it takes you only an hour or two. (Don’t expect your first few to be that quick, though; it does take practice.)

Although there are, fortunately, lots of good ways to

build TEA nitrogen lasers, there are also lots of bad

ways. It is particularly important to remember that if

you try something and it doesn’t work, you need to

document it carefully anyway, because you will almost

certainly need the information later on, in order to

figure out something that does work. You will

probably also need the information in order to avoid

repeating the same error[s]. It is a great relief (and

sometimes a large surprise) to return to your notes,

possibly months or years later, and find something you

did that you may have forgotten about, and to have at

least some of the information you need in order to

understand how it worked ...or didn’t.

In order to build one of these, you will need the following things:

You want your sheet of shim stock, or whatever you end

up using, to be smooth and flat; if it is buckled or

wrinkled, it won’t make good contact with the

dielectric. However, a small amount of buckling or

wrinkling that is near the edge, as long as it is well

away from the upper capacitor plates, should not be a

problem.

For the upper plates I used small sheets of brass (2" x

12") that I got at the hobby shop. In the first version,

these also serve as the electrodes of the laser. They

are available in various thicknesses; I found 32 mils or

even 64 mils to be convenient, for reasons I’ll

get into when I describe some improvements.

These lugnut covers are available at truck stops, and

they are not very expensive, but I decided to use a

different design here, partly to find out how well it

would work and partly because the parts that I needed

for it are available at hardware stores.

I use crimp connectors, but you can avoid them if you

want or need to.

One unusual item that I have found helpful is a special

glue that is electrically conductive. The version I used

to buy has been replaced, and I have not tested the new

version yet, but I expect it to work just as well. I get

this glue from the

Electron Microscopy Sciences division of emsdiasum.com.

(The link is to their catalog page for adhesives; look

for the word “Conductive” a little less than

1/3 of the way down the page if you want to see all of

the relevant offerings; the material I will be using in

the future, when I have used up the bottle I currently

have is “Silver Conductive Adhesive 503”.)

Strictly speaking, conductive glue is not necessary; but

it does help avoid sparking where close contact is

needed. You can see it, for example, under the back end

of the spark gap in the overview photo of the laser

where I mention replacing the resistors with an

inductor, just before the first photo that shows the

output.

You will also need some weights, to hold things down. It

is important to get the capacitor plates into good

contact with the dielectric and the dielectric into good

contact with the baseplate, because air will decrease

the amount of capacitance; because of that, it also

decreases the amount of energy that the capacitors can

store at a given voltage, and interferes with the

performance of the laser. In the more complex versions

of the design you also need to insure good contact

between the electrodes and the capacitor plates, and you

need to hold the electrodes in place so they don’t

slide around. I have used a wide variety of objects for

this purpose, several of which you can see in the

photos: bricks, worn-out sealed-cell batteries from a

UPS, pieces of scrap metal, and so on. One of my weights

is a spice jar filled with small nuts and bolts. (Jarrod

Kinsey has sometimes used cans or jars that he has

filled with pennies; I like nonconducting weights,

because if you accidentally touch one you won’t

get shocked, so I would use glass or plastic jars,

rather than metal cans.)

For ease and convenience, I have taken the power supply

out of an old electronic air cleaner. Here is the air

cleaner before I disassembled it:

This is what the right side looked like with the cover

off:

The power supply consists of a transformer and a small

circuit board. Here it is on its new base, with a

switch so I can control it:

(Please note that this is just a temporary

setup. Although the high voltages are insulated it is

not safe to have line voltage exposed as it is here, and

I will eventually enclose this supply in a

well-ventilated insulating box.)

I made a voltage divider by putting a 100-million-ohm

high-voltage resistor in series with an ordinary

10,000-ohm resistor, and I used the divider to measure

the output voltage from this supply. The schematic

diagram on the bottom of the case says that the supply

puts out 5500 VDC at 0.3 milliamps, but that turns out

to be a description of one polarity, not both: I

measured roughly 5980 volts on the positive terminal and

roughly 6390 volts on the negative terminal, for a total

of over 12 kV. This is the open-circuit voltage; when

the supply is providing current to a load, the voltage

is lower.

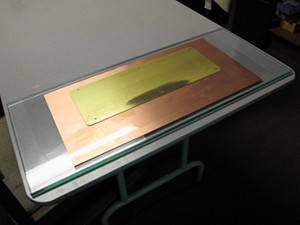

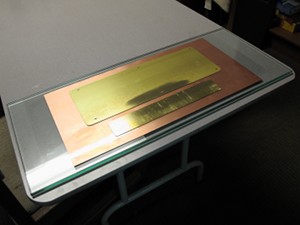

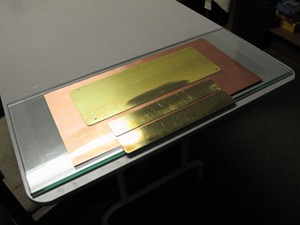

I have been using two bases for this laser; both of them

are glass, and I got both at thrift stores. (I used

glass because the lower electrical plate of the laser is

at high voltage, and I wanted to keep it isolated from

the table. In addition, glass is generally flat, which

is important.) The glass pieces I found are intended for

use in the kitchen, and they have pebbly top surfaces; I

decided to live with that, but if you find one that has

an extremely flat bottom surface you may want to turn it

over and use the flat surface as the top. Alternatively,

a plain piece of window glass will work, but you should

make sure that the edges are not sharp. If you prefer to

avoid glass, various kinds of plastic sheet can be used

to insulate the high voltage from the bench or table;

just be certain that the upper surface is clean and

flat.

I used a piece of single-sided circuit board as the

baseplane of the laser (it would ordinarily be the

ground plane, but because of the way the power supply is

configured, it is definitely not at ground potential),

largely because I have several pieces, acquired on eBay

some time ago, that are of an appropriate size. Also,

although it is quite thin, this material is just stiff

enough that the pebbly surface of the glass underneath

it is not a problem. (The board is so thin, in fact,

that it can be cut with a pair of scissors. I

don’t recommend doing that if you have a tool that

is better suited to the job, however, because cutting

circuit board isn’t a very nice thing to do to

your scissors.)

Brass shim stock is a good alternative that you can get

at some hardware stores, and also on eBay. It works at

least as well as the circuit board. Shim that is 0.003"

or 0.004" thick should be suitable; if it is any thicker

it starts to become more difficult to cut, so you may

want to obtain a pair of tinsnips if you don’t

already have one.

The next step is to find a piece of plastic that can

serve as a dielectric. I had originally intended to use

overhead projection transparencies, but then I went to

an office supply store and priced them: $40 for 100

sheets. I eventually found some at a thrift store for a

much more bearable price, but they are only 0.004"

thick, and that isn’t enough to handle the full

output of the power supply, so I went to the hobby shop

and bought some styrene sheets that are 0.010" thick and

about 18" long. These work quite well, but it is

important to remember to get the long size if you are

using long electrodes: the brass sheets that I used as

the upper plates of the capacitors in my initial

versions of the laser are 12 inches long, which meant

that I needed a dielectric sheet at least 13 inches

long, and preferably longer. High voltage will jump

across insulators if it can, and you need to provide a

margin of more than half an inch all the way around the

capacitors. Likewise, when I use brass sheets that are

4" x 10" (another size that I can get at the hobby shop)

it is easier to deal with the length, but I need to use

a piece of plastic that is well over 8½ inches wide, and

because of the spark gap, which I have positioned at one

edge of the laser, I really need at least 10 inches of

width.

You will need a spark gap to conduct electricity from

one of the capacitors to the ground plane. I made my gap

out of a pair of 1/4-20 carriage bolts, as you can see

from the photos, below. (Figure 9 shows the initial

version.)

Note: It is not necessary to position the spark

gap where I did. You can put it almost anywhere you

want, provided it doesn’t interfere with some

other aspect of the design. There are some people who

claim that it has to be in or near a corner of the

capacitor, particularly if you want to achieve what is

referred to as travelling-wave excitation; but if you

think about that claim you will notice that in order for

it to be valid, the gap would have to switch in a rather

small fraction of a nanosecond. That’s

considerably faster than is physically possible for a

design of this type. (If you actually have a fast

photodiode and a fast oscilloscope, you can check this

for yourself. You will find, as I did and as you can see

in Figure 26, below, that there is exactly zero chance

of it being accurate. OTOH, it is typically possible to

wedge the electrode spacing so that you get most or all

of your output from one end of the laser.)

(I’m going to presume that you have acquired the parts and materials you need, and that you have a power supply.)

Start by rounding the corners of the brass sheets that

will serve as the top plates of the capacitors. (In this

version, they also serve as the electrodes of the

laser.) Sand the edges at the corners and ends to smooth

them — sharp edges can cause sparking where you

don’t want it, and can sometimes even make it

easier for the high voltage puncture the dielectric,

which immediately causes the laser to fail until you put

a new dielectric into place. You can also make sure that

the edges that face each other and serve as electrodes

are straight and parallel to teach other, and it’s

a very good idea to smooth them and then polish

them. Here are two views of one of the electrodes from

the first version I built:

As you can see, the laser can be made to operate even if you don’t smooth the edges of the electrodes; but it won’t work as well, and it won’t be as easy to adjust. Here is a detail of two new electrodes that I have smoothed and started to polish:

Because the brass pieces are formed by stamping them out

of larger sheets, one face of each is slightly convex

and the other is slightly concave, and the sheets are

almost never really flat. It’s a good idea to put

the convex faces down, as this prevents air from being

trapped under the sheets. Also, if there are sharp edges

it holds them a tiny distance up above the dielectric,

which helps avoid punctures.

The fact that the sheets are not fully flat is another

reason for using weights. In addition to the slight

edge-to-edge curvature imposed by the manufacturing

process, they can also be slightly bowed from rough

handling. If the middle of the sheet is high, you will

want more weight there. (That was what I found with some

of mine, but “your mileage may vary”. If the

ends are high, you can either put more weight there or

very cautiously bend the strips so that the middles are

slightly higher than the ends.)

You need a way to conduct high voltage from one sheet to

the other, so that they both charge correctly. I

originally used resistors, but the first ones I tried

had too much resistance, and the channel sparked every

time the laser fired, so I changed over to an inductor

that I made by winding a few turns of high-voltage wire

around a surplus ferrite core. (You can see this

inductor in several of the photos; it is the blue toroid

with the red wire wrapped around it.) Later I returned

to resistors, but I used a lower value. Either method

can work, but when I tried 200 ohms I found that it is

not enough; a value that low will steal some power from

the discharge. A combination of resistance and

inductance works better than resistance alone, and if

the inductor has enough turns resistors are not even

necessary.

If you use resistors at all, btw, it’s a good idea

to make sure that they are rated for high voltage;

alternatively, as you can see in some of the photos

here, you can use resistors that are encased in ceramic

envelopes and are rated to dissipate several watts: they

seem to withstand the voltages involved. As I say,

though, if your inductor is big enough you won’t

need resistors.

For your inductor, you will need something like 25 or 30

turns around a nonconducting cylinder that is perhaps an

inch and a half in diameter. (I haven’t taken the

time to find the minimum viable number of turns; it may

be less than 25, and it will depend on the diameter of

the cylinder and the turn-to-turn spacing of your coil.)

For convenience and stability you can wind the wire

around anything strong enough to hold it, perhaps a

piece of PVC plastic plumbing pipe if you want to be

relatively fancy about it. I am not fancy; I use the

cardboard cylinder from a roll of toilet paper, which I

stiffen by soaking it with cyanoacrylate adhesive

[“superglue”]. I glue the ends into place

with cyanoacrylate adhesive. This works well, at least

on the type of wire I use.

Here is a photo of a combination that I made; the

inductor is 25 turns, and the resistors are 100 ohms

each. The wire has fairly thick insulation (0.045", a

little over 1 mm); it was the thickest I found at my

local hardware store. It works quite well, and my later

versions do not use resistors.

The upper electrode of the spark gap in my initial

version is mounted on a small piece of brass shim stock

that is attached to the capacitor plate of my laser with

conductive glue, though it is probably sufficient to

hold it down with a weight. In the first version of the

laser I set the lower electrode of the spark gap down so

that it was partly on the ground plane and partly on the

dielectric, in a configuration similar to the one that

Jarrod Kinsey uses (I have a link, above, to a photo of

one of his lasers), and although I used some conductive

glue I also put a weight on it to help hold it in

place. Here is that original gap in operation:

You don’t necessarily need the shim stock: it is

probably fine to connect both sides of the gap the way I

did the lower side, and hold them both down with

weights. That may be trickier to adjust, though —

the spark will jump along the surface of the plastic

unless you put some sort of blockage in place to prevent

it from doing so. (The laser could possibly work with

surface sparks in the gap, but probably not very well;

and the surface sparks would eventually damage the

plastic, after which the high voltage would puncture it

and you would have to replace it. I often use a short

piece of plastic I-beam from the hobby shop as a block

in this sort of circumstance; you can see a piece in

Figure 25, behind the gap. It is necessary to glue the

I-beam (or whatever you use — a cable tie or a

piece cut from one could also work) to the dielectric

with something that is a good insulator at high

voltages, because otherwise the sparks will just sneak

under it. I use “corona dope” (there are

several versions, any of which should work).

Here are some stages in the assembly process:

(Note: this sequence shows wider plates, a

different dielectric, and a more advanced version of the

spark gap than you see in Figure 13. I hope I

don’t have to keep saying that there are lots of

good ways to build these devices.)

(At a later point I replaced the inductor shown here

with the combination of inductor and resistors that you

can see in Figure 8 and in the photo at the top of the

page.)

Note: I connect one side of the power supply to

the baseplane, and the other side to the capacitor plate

that doesn’t have the spark gap on it; but

the laser should work with the connection on either top

plate, as long as both capacitors get charged. You can

test to see whether one way works better with your laser

than the other. You should also test to see which

polarity works better. I usually find that I get better

operation if I connect the positive output of the power

supply to the top plates of the capacitors and the

negative output to the baseplane, but your laser may be

different.

Here is a picture of the output (the small bright spot),

causing a piece of white paper to fluoresce. (The large

diffuse area is light from the spark gap.)

A verbal description of the process of putting one of

these together is likely to be somewhat confusing, so

here is a video to accompany and supplement the photos

above. In this video I build a slightly later and more

advanced version of the laser. (I had just taken it

apart, which is why the voiceover begins the way it

does.)

(Note that the spark gap design you see in this video is different from the ones I show in the photos above. Any of these designs will work.)

Because all of the pieces were already shaped and ready,

because I had just disassembled the laser, and because I

have a fair amount of experience, it took me only 3

minutes and 30 seconds to get it running reasonably

well.

Although this video can give you a fair sense of how to

assemble a simple laser of this type, it is essentially

guaranteed to give you an exaggerated notion of how easy

it is to get one of these machines correctly

adjusted. For one thing, lasers of nearly any sort

almost never work when you first put them together. I

had already built this one several times, though, so I

had a fair sense of some key parameters — for

example, the best distance between the electrodes, which

is about two millimeters or a bit less for this

design. In addition, I have to confess that I have, on

more than one occasion (and as recently as a day before

I wrote this paragraph), spent several hours at a time

trying to adjust a TEA nitrogen laser so it would work

correctly. You need to be patient with the laser, and

you need to be especially patient with yourself.

You also need to remember safety precautions when you

are tweaking, as there is often high voltage on parts of

the laser after you turn off the power supply.

Always turn off the power and short out the HV

before you touch any part of the machine.

First, here is a view of one section of the channel in

normal operation. The tiny white dots on the surface of

the cathode are expectable. They probably indicate that

the channel is being driven strongly, but they are not

necessary for lasing, and I don’t see them as much

when the electrodes have been polished.

Notice that the discharge is not very bright. This is

normal. In fact, it is common to obtain good laser

output from a discharge that appears quite dim to the

eye. (Remember, we are looking for strong UV emission

here, and that does not necessarily correlate with

strong visible emission.)

Note, added later: As I continue to work with

these lasers and to refine my designs, I get to adjust

and observe them quite a bit. In the process I begin to

suspect that I get best output from a discharge that is

just on the edge of sparking, or is showing occasional

bright sparks. My initial guess is that although more

preionization produces a smoother and cleaner discharge,

it also takes more of the energy that is stored in the

capacitors. This decreases the amount that is available

to drive the laser channel.

Here are some conditions that typically do not result in lasing:

If you do not get bright sparks when you first turn on

the power, but you do get them every time the laser

fires, the real question is whether they interfere with

lasing. If there are only a few and they occur only

sporadically, you can probably ignore them; but if there

are lots of them you will want to readjust the laser.

That should get you better output, and it will also help

prevent the electrodes from getting too badly pitted.

If the sparks always seem to occur at the same locations

you probably want to disassemble the laser and clean up

any jaggedness or irregularities on the working surfaces

of the electrodes (and preionizers).

In any case, you can often get some output even with a

fair number of sparks, as you can see in these photos:

If you encounter problems that I don’t list here,

you may want to send me an email message. I can’t

guarantee to be able to help, but at least there’s

a chance.

There are various changes you can make in order to get

better performance from your laser[s]. Some of these

involve fairly extensive rebuilding, some don’t.

First: separate electrodes

As you can see in Videos 1 and 2, I added separate

electrodes to the laser. This helps in several

ways. First, moving the discharge away from contact with

the surface should cause it to take longer to damage the

dielectric. Second, the edges of the dielectric

aren’t always very flat, and sometimes the bumps

or ripples obstruct or interfere with the beam. Raising

the discharge up, even a little, usually eliminates this

problem. Third, having separate electrodes makes it

easier to adjust the channel width, because the

electrodes are not held to the dielectric by

electrostatic attraction, the way the capacitor plates

are. Fourth, having separate electrodes makes it easy to

test various thicknesses and different edge

profiles. (See the addendum about this, below.)

About electrodes: many people who build TEA nitrogen

lasers use cylindrical electrodes, but my experience has

been that round bars want to roll out of position at the

most inconvenient times, so when I built this laser I

chose a different path. I acquired some brass strips at

the hobby shop instead. They turned out to work quite

well. Jarrod Kinsey uses steel rods as electrodes, but

he bends the ends, as you can see in the photo of one of

his lasers that I link to above (where I discuss the

spark gap), partly to prevent them from rolling.

Addendum: Electrode profile

I can’t tell you how your laser will behave,

but I can tell you that when I smoothed and

rounded the edges of the electrodes I was using in mine

I got a significant improvement in performance, and

when I polished them I got another slight improvement.

The discharge is more uniform and a bit less likely

to spark, and the laser is easier to adjust.

Addendum: Angled or wedged electrode spacing

If you’ve built and operated one of these lasers,

you will have observed that there is almost always more

output at one end of the laser than at the other. You

can adjust the electrodes to optimize either end, but

(at least on my lasers) one end is usually easier to

optimize than the other. (Which end this is can change

as you tweak things, though, so you need to be alert.)

It is usually possible to adjust the channel so that it

is slightly wider at one end of the laser, and you can

sometimes get most or all of the output to come from

that end.

I should note, however, that my best current designs

have not been behaving that way. If I attempt to

minimize the output from one end I soon begin to get

less output from the other, and in fact I seem to obtain

best output [at whichever end of the laser is better at

the moment] when the output from the other end is only a

little below its best level.

Second: Preionization

If you have already built and tweaked the initial

version of this laser, you know that it is difficult to

position the edges of the channel to produce a clean and

even discharge. If the electrodes are too close together

or too far apart (or if at least one of them is not

straight), you get arcs and sparks. Finding the

“sweet spot” where the spacing is optimal is

not easy, and can take quite a bit of time and a lot of

fussing.

One thing you can do to make adjustment slightly easier

(and improve the performance at the same time) is to

create a much smaller, separate discharge that starts

before the main discharge and fills the laser channel

with ions and UV light. (Hence the name,

“preionization”.) Preionization is

absolutely crucial for high performance.

If you have separate electrodes, the simplest way to

accomplish this is by sharpening the edge of one of the

capacitor plates. The best shape is not necessarily

obvious, and the positioning of the preionizer is also

important, so you are in for some fussing and fiddling.

After some thought and experimentation, I added separate

preionizers between the capacitor plates and the

electrodes. (Figures 22 and 23 show this configuration.)

Although this makes more things you need to adjust, so

it takes quite a while if you really want to optimize

the laser’s performance, I think it may be worth

the trouble. On the other hand, since I first wrote this

posting I have had very good results using the capacitor

plates as preionizers; they are ideally positioned to

create a surface discharge on the dielectric.

I am using a shape that is actually similar to the edge

profile that

Alfonso Torres Rodríguez

uses for the electrodes of his high-performance

TEA lasers. I create the shape by rough-sanding the

upper edge of one of the capacitor plates at about a

45° angle, but not all the way down — I leave a

little bit of the original edge. It is difficult to

photograph, but

here is Alfon’s image

of his electrode profile (red circle, with diagram below it),

here is a clearer view of one of his earlier profiles,

and here are two views of one of my preionizers, first

showing the narrow bottom edge, and then showing the

angle above it:

[Remember that because I am using this for

preionization, not as a channel electrode, it is

positioned with the narrow edge down, close to the

dielectric.]

It is surprising how rough and informal the profile can

be and still work, though a smoother and more even

profile will give you better performance.

You will have to tweak the various spacings to find what

works best. I must caution you (again) that this process

is usually quite slow, and can sometimes be tedious. I

often find that when I am attempting to tweak at one

end, the performance at the other end changes even more.

In the best-performing versions of the laser, btw, I

have preionizer profiles on both sides of the channel,

and I find that the spacing between them seems to need

to be slightly larger than if I use one plain edge and

one shaped edge. (When the capacitor plates are also

serving as preionizers, the optimal spacing seems to be

at least twice the channel spacing, and possibly even

more.)

Here are two photos taken during assembly. In the first,

the preionizers are in place, in preliminary locations;

they may end up somewhat closer together after I finish

tweaking for best output. In the second I have added the

electrodes, also in preliminary locations. (The next

step is to add weights to hold everything firmly in

place and ensure good electrical conduction. In addition

to the half-brick you see in these two photos, weights

of several sorts are visible in several places,

including the photo at the top of the page and Figure

13.)

Third: the spark gap

The original gap design (see Figures 9 and 13) worked,

but I wanted something that was physically more stable

and that I hoped would switch faster, so I changed to

the design that I show in Video 1. Here is a photo:

(The spacer you can see in this photo did not work well, and is obsolete. I tried various alternatives, but eventually I changed over to the version of the spark gap that is shown in Figure 29, which is stabilized by its components. See the text for details.)

The spark gap spacing determines the voltage at which the laser will fire. If the electrodes of the gap are too far apart, the power supply will be unable to deliver enough voltage to cause the gap to conduct. If they are too close together, the gap will fire very often, and typically the lasing (if you get any) will be weak. If nothing other than the piece of brass shim stock holds the upper electrode in place, it will bounce up and down when you run the laser. This can cause peculiar variations in the firing rate, but at least in some cases it can actually stabilize operation.

Important: remember to use an insulated tool when you adjust the spacing of the gap, unless the power supply is off and you have shorted out the HV.

Addendum: a “start” capacitor

There is another thing you can do to the spark gap that will improve the operation of the laser. It turns out that an additional capacitor, connected directly across the gap and positioned close to it, causes it to form a better conduction channel and to form the channel more quickly. This has two results: the laser works better in general, and the pulse-to-pulse uniformity is much improved. You can see this capacitor in Figure 25, below; it is the small brown cylinder, just to the left of the gap. (It should be as close to the spark gap as is practicable.)

Because the capacitors that comprise the laser are not

very large themselves (perhaps 1500 to 5000 picofarads

each, depending on construction details), the

“starting capacitor” has to be quite small;

I am currently using a 25-picofarad

“doorknob” capacitor that I had in my

junkbox, but there should certainly be other ways to

accomplish this. The precise value is not very

important, as long as the value is small compared with

the capacitances of the laser. You do need to be sure,

btw, that it will handle whatever voltage your power

supply can deliver. Here is a photo, showing the gap

with a start cap in place:

Here, in case anyone is interested, is an oscilloscope trace:

(My apologies for the electrical noise that is

superimposed on the trace; it is difficult to shield the

detector and the oscilloscope from the nasty EMP that

the laser generates when it fires. The noise, btw,

looks

very much the same

from trace to trace.

I guess that the way it is generated and the way the

scope responds to it don’t change much.)

In this trace it takes about 24 or 25 nanoseconds for

the electrical pulse to reach peak power. (In some

others it seems to be as fast as about 16 or 18 nsec.)

The laser pulse occurred at about 18 nsec, but the light

from the laser had to travel about two feet farther than

the light from the spark gap (it went out to the side,

to a mirror that reflected it into the detector), so it

reached the detector about 2 nsec later than it would

have if the pathlengths had been the same. I have put a

mark on the trace where it should be. (I find it

interesting that even with a simple DIY laser we are in

a regime where this is an issue. Making comparative

measurements involving really short laser pulses

must be a nightmare.)

It would be best for the laser to reach threshold when

the electrical power is just reaching its peak, but at

least it’s fairly close. I also suspect that

it’s better to be on the upslope than on the

downslope. Either way, the laser pulse is only about 1

nanosecond long, the electrical pulse is far longer, and

it is therefore clear that most of the energy stored in

the capacitors is wasted. This is not (and cannot be) an

efficient laser.

If you are really interested, you can redesign the spark gap so that it is externally triggered. That will give you far more control over when and how often the laser pulses. It is also likely to improve the performance, partly because it allows the power supply to charge the laser up until you trigger the gap, rather than when the gap fires on its own, and the capacitors store more energy at the higher voltage.

I must, however, note that a triggered spark gap without a trigger pulse is an untriggered spark gap. I am, at least initially, using a commercial trigger unit that we bought on eBay, because I don’t have time to design and build one myself right now. (If I do end up building one for this project, though, I will post the design here. I will note that a triggered gap of this type tends to require a that doesn’t have to have much energy in it, but it does need to be fairly fast — the risetime should be less than 1 microsecond. The pulse from an automotive spark coil is much too slow, though there may be ways to finesse that.)

To construct the new upper electrode for the gap, I took

a short brass 1/4-20 bolt and drilled a hole down the

middle of it, or as nearly down the middle as I could. I

then drilled out the hole with a slightly larger bit, so

that I could easily fit a piece of glass capillary

tubing down it. I am using melting-point capillaries

that we acquired on eBay for a different project. The

brand is not crucial, and in fact there are even several

types of capillary tube that will work, not just the

ones for determining melting points. The ones I’m

using came in a container that looks like this:

One end of each tube is closed, but I already had some

that I had shortened by cutting off the closed end. (You

need to be quite careful when you do that, as these are

thin-walled and very delicate. It’s a good idea to

wear gloves. I moistened the outside of the tube, scored

the wall lightly, and just pulled. I cut several of them

this way, and most of them broke cleanly.) I also

drilled a smaller hole, one that the capillary tubing

would just fit into, through an acorn nut, as close to

the peak as I could get it. Here is the preassembled

head, but without the trigger electrode:

NOTE: unless the holes line up very nicely, it is important to attach the tubing to the bolt with a flexible glue. (Yes, I found this out the hard way, by using CA glue at first, and had to remove the remains of the tubing from the bolt after I tried to put the acorn nut on. As you can see in Figures 29 and 30, aquarium caulk is your friend here.) In case it isn’t obvious, you do not want to glue the tubing to both the bolt and the acorn nut, as that would make it difficult or impossible to adjust. You could glue it to the acorn nut instead of the bolt, but the bolt has more contact area and is not going to be exposed to hot plasma. For this reason I didn’t try plastic tubing, though that might also work. Jarrod Kinsey has suggested the thin tubes that often come with (for example) aerosol cans of lubricating oil as a possibility here.

I am using a piece of broken jeweler’s saw blade as a trigger electrode. It was handy, and it is fairly hard steel, so I hope it will last a little while. (This is really only the second time I have built a triggered gap, and the first one was much different, so I do not yet know whether the saw blade was a good idea. I’ve put over a hundred shots on the laser with the new gap in place, though, and it seems to be fine.)

Here is a photo:

As seems to be usual with this style of gap (if I recall correctly, it is called a “trigatron”), I have the positive output of the trigger-pulse generator connected to the trigger electrode and the negative output connected to the acorn nut. I also have the positive terminal of the power supply connected to the upper plates of the capacitors. Initially, I was using only one “starting capacitor”, as you can see in some of the previous photos, but later I added a second one.

(Parenthetical note: I tried to get an oscilloscope trace of the light from this gap, but the electrical noise was so bad that I was unable to do so.)

I eventually changed the gap design again. I am now using a carriage bolt as the top side, just as I do for the free-running versions of the gap; I drill the hole starting at the head end of the bolt, so that it is centered where that’s important.

Fourth: the dielectric and the capacitor plates

I was able to get some acetate sheet (which you can see

in Figures 10-12 and 22-23) from a vendor on

eBay. Acetate has higher dielectric constant than most

of the other plastics I’ve been using, which means

that at any given voltage, a capacitor made with acetate

will store more energy than a capacitor made with, for

example, styrene, provided the sheets are of the same

thickness. The capacitance is higher if the dielectric

is thinner, and the acetate sheet that I acquired is

only about 6.5 mils thick, which gives it another

advantage over the 10-mil styrene sheet I was using

earlier.

Because this sheet is so thin, however, it can’t

handle as much voltage as a thicker sheet, and I have to

adjust the spark gap so it fires about 2 or 3 times a

second. At one point I allowed the time between pulses

to get too long, which let the voltage on the capacitors

rise too high; a puncture promptly developed in the

sheet I was using, and the laser stopped working until I

swapped it out and tightened the spark gap

spacing. (Even 2 pulses per second doesn’t really

seem to be enough; the voltage has punctured two more

pieces of acetate sheet since I first wrote this

paragraph, one of them twice. Fortunately the first hole

was very close to a corner, and I was able to move the

capacitor plates slightly to avoid it. [I put a droplet

of corona dope over the hole to prevent sparks from

going through it.]

In addition to finding a thinner dielectric with higher

dielectric constant, for this version of the laser I

changed to capacitor plates that are 4" x 10", so they

have more area. (You can see these plates most easily in

Figure 11, but they are also visible in Figures 12, 22,

and 23.) This also increases the capacitance, and thus

the amount of energy the capacitor stores at any given

voltage. (With these plates, though, I have to use

separate preionizers because the electrodes are 12"

long.) The capacitance, btw, calculates at just over 5.5

nf; but when I measured it I found that the actual value

was only about 4.2 nf. I am not entirely sure what is

responsible for the difference, though it is entirely

possible there is still a small amount of air trapped

between the plates and the dielectric.

When I built the triggered gap I returned to 10-mil styrene and 2" x 12" plates, because I wanted to be able to pause between pulses. With the thin acetate sheet, that would not have been possible.

All of the lasers on this page use a circuit topology

that is probably best described as a simple

voltage-doubling circuit, though it does not actually

double the voltage. (There doesn’t seem to be a

better term for it.) There is also a different topology

that you can also build, a Charge-Transfer Circuit.

In the doubler circuit, you charge up both capacitors

and then short-circuit one of them to ground (or, in the

machines I describe here, to the opposite power supply

polarity). For reasons that are described elsewhere,

this causes a large voltage to develop across the laser

channel, which is between the two capacitors, very

rapidly. The flow of current from one cap to the other,

across the channel, drives the laser.

In the CT circuit, on the other hand, you charge up one

capacitor, which serves at the main energy storage point

for the laser. You then discharge it into a second,

smaller capacitor through a high-voltage switch

(typically a spark gap) that is between them. The

smaller capacitor starts the laser channel conducting,

and then both capacitors drive the laser.

Each of these circuit topologies has advantages and

disadvantages. The doubler circuit is efficient,

symmetrical (it has been found, both theoretically and

experimentally, that it provides best performance when

the two capacitors have the same value), and easy to

construct. The CT circuit is not symmetrical, is usually

less efficient, and is often somewhat less easy to

build; but at its best it can perform quite well.

(See the nitrogen lasers built by Alfonso Torres

Rodríguez; there’s a link to his site,

above.)

The main store of a CT circuit (often referred to as the

“dumper” capacitor) can have relatively

large value, and it does not have to be as fast as the

capacitors in the doubler circuit, both of which must

drive the channel directly.

One other advantage of the CT design is that you can

eliminate the charging inductor or resistor-inductor

combination. You are only charging one capacitor, so you

don’t need or even want a connection to the other

one. (In principle, you could put the connection between

the peaker capacitor and the ground plane,

to discharge the peaker between pulses; but I

have not seen very much difference with a discharging

inductor in position, so I usually don’t bother

with one.)

Here are photos that show the assembly of a

straightforward CT design that is closely related to the

doubler designs I’ve presented above. The dumper

capacitor is a 6" x 16" piece that I cut from a brass

kickplate. The peaker capacitor is a brass strip, 2" x

12". This laser uses separate electrodes, which raises

the channel up from the surface of the dielectric and

allows the top plate of the peaker to be used as a

preionizer. The spacing between the top plate of the

peaker and the other brass strip is not optimized in

these photos. Note: on the side of the channel that is

connected to the baseplane, there is no dielectric. The

brass strip on this side, which supports the electrode,

should be enough thicker than the top plate of the

peaker cap to compensate. (With 10-mil styrene as the

dielectric, I used a 16-mil strip as the peaker and a

25-mil strip on the low side. When I changed over to

5-mil Dura-Lar™ [a polyester film that is similar

to Mylar] I used a 25-mil strip as the peaker, and a

32-mil strip on the low side. I use the same combination

when I have two of the 5-mil sheets under the dumper,

because I am still using only a single sheet under the

peaker.)

I used a thick glass plate as a base, partly because

there is enough weight on the laser when it is assembled

that if I didn’t provide a stiffener it could flex

the top of the table, depending on where I position

it. That would put a curve in the channel and prevent

the laser from working properly.

Here is a view of the channel, with two sheets of 5-mil

Dura-Lar as the dielectric for the dumper and a single

sheet as the dielectric for the peaker. The dumper for

this version of the laser was a piece of brass shim

stock, 6" wide and about 28" long. (The baseplane for

this version of the laser, which I built in February of

2012, is a piece of 12"-wide brass shim stock, also

about 28" long.) I measured the dumper capacitance as

just about 10 nf and the peaker capacitance as 2.9 nf,

but I don’t know how accurate my meter is. The

channel was adjusted extremely well, and the unfocused

beam easily drove a cuvette of “Optic

Whitener” that was at least 8" away from the end

of the channel, with the laser pulsing a bit faster than

1 Hz. There are occasional bright sparks, but very few,

and they do not appear every time the laser fires. The

tiny white sparks (which Jarrod Kinsey refers to as

“icicle sparks”) do, on the other hand,

appear every time. They are on the cathode (negative)

side. There is a dim violet glow in the channel when the

laser fires, but it can be hard to see, and the camera

doesn’t seem to pick it up very well. (Remember,

we are looking to get UV out of the laser, not visible

light, so a discharge that appears dim to the eye is not

necessarily underpowered.)

With 5-mil polyester film as the dielectric for both

capacitors the channel needs to be wider for best

operation, and it has more and longer “icicle

sparks”. It may also require more preionization.

Unfortunately, unless the laser is pulsing several times

a second, a single 5-mil film used as the dielectric for

the dumper typically lasts only a few hundred to a few

thousand pulses, so I am using two sheets.

Here is another Charge-Transfer design.

It uses a small Marx bank as its dumper capacitor and

provides even better performance, but at the expense of

added complexity.

Here are some reference points you can use if you want to.

At some point, you probably start coming up with your

own ideas for improvements, or for entire designs. This

isn’t something that can be placed in the

sequence, so I am not giving it a number.

I encourage you to try various ways to improve the

performance of your laser or lasers, and I strongly

suggest that you keep a comprehensive notebook that

includes photos, and you should take photos not only of

things that worked but also of mistakes, and of things

that didn’t do what you wanted them to or thought

they would. It can save you from much headpounding, and

from having to learn things repeatedly.

One of the most common uses for the nitrogen laser is as

a pump source for organic dye lasers. As I mentioned

above, in the listing of milestones, this can serve as a

rough indication of the output power.

The total energy stored in the original version of the

laser (10 mil styrene and 2" x 12" plates) was probably

close to 200 millijoules. That version could drive a

small dye laser if I used a cylindrical lens to focus

the beam onto the front of the dye cuvette. Some of the

later versions can drive a small dye laser even if I

don’t focus the beam. (I’ve mentioned this

as one of the progress steps, above.) The photo on the

left, taken from in front of the cuvette, shows this

with nitrogen in the channel. After I got that version

adjusted a bit better I was able to get enough output

even with air in the channel. (Photo on the right, taken

from behind the cuvette.)

(The brighter spot is the dye solution using the walls

of the cuvette as mirrors. The tall diffuse stripe is

lasing without feedback, often referred to as ASE

[“Amplified Spontaneous Emission”].)

Although I used a commercial dye and a fused silica

cuvette in these photos,

Video 4

shows a dye cell I built out of microscope slides, glued

together with silicone aquarium caulk. In this video I

use the focused output of the nitrogen laser to drive

three different commercial fountain pen inks. (I have

actually lased five fountain pen inks so far.)

I’ve already mentioned “Optic

Whitener”, which is another excellent laser dye

for the DIYer, and you can even get fluorescent dyes

from some highlighter markers, though they are not

always optimal for nitrogen laser pumping. (If you use

isopropyl alcohol to extract the dye from a Sharpie

“Accent” yellow-green marker like the one

that you can see in the photo at the top of the page,

you get a solution that seems to work fairly well. It is

quite concentrated, and you will need to dilute it, just

as I diluted the inks I used in the video.)

If I focus the output, the nitrogen laser can also drive

a piece of commercial fluorescent plastic:

The edges of the sheet are not smooth or glossy, so its

output is very diffuse. I decided to clean up one edge,

but polishing it would have been difficult, so instead I

glued a microscope slide to it, using cyanoacrylate

adhesive (“CA”; “superglue”).

(In retrospect, I should have used either a different

type of CA, or epoxy. The thin glue is difficult to

control, and it got on some places where I didn’t

want it.)

This resulted in a slightly improved output pattern:

(Taken with air in the channel of the nitrogen laser.)

One slide provided enough improvement that I decided to

add a second one. When I line up the beam of the

nitrogen laser so that it is perpendicular to the slides

and the dye can use them as mirrors, this works quite

well:

My designs started as variants of designs developed by

Jarrod Kinsey; I have introduced a number of changes,

partly for ease of construction, partly because of the

materials I can get, partly because of the way I think

about the issues involved here, and partly to point up

the fact that this is not a “one right way”

situation. Just because I do something a certain way

does not mean you have to do it the same way if

you can’t find the part or material that I use, or

even if you just want to do it differently. If you

decide to do something differently, though, or if

circumstances oblige you to, you will want to think it

through before you build it, so you’ll have some

idea of how your version is likely to work, ...unless

you are willing to spend some time and effort on what

could end up being a lengthy trial-and-error method. [I

am hoping to provide some background information on a

separate page, to help you understand how these lasers

work and what the important parameters are. I also

provide links to pages that other people have written

about their nitrogen lasers, for comparison.]

Jarrod’s designs, in turn, are based partly on

designs and suggestions from other DIYers including

myself (there are no one-way streets here!) and Milan

Karakas; partly on his own experiments; and, though not

as directly, partly on articles that have been published

in the scientific literature.

Just as I made a number of cogent suggestions to Jarrod

as he developed his designs, he has made a number of

cogent suggestions to me as I developed the designs on

this page, and I am indebted to him for his help on this

project. I am likewise indebted to Milan Karakas, who

asked several key questions and provided crucially

important advice relating to the performance of the

lasers, particularly with regard to preionization and

switching.

The preionization method that I use in the improved

versions of the laser was inspired by a feature that

Alfonso Torres Rodríguez uses in his TEA

lasers. My spark gap design was partly inspired by two

high-speed spark gap designs that I encountered in the

scientific literature, and partly by what I could get at

the hardware store. The power supply is my own idea.

I must also acknowledge my indebtedness to Ernest

E. Bergmann, who developed some of the earliest

room-pressure nitrogen lasers, and whose papers have

been extremely helpful to me; to Professor Mark Csele,

who has done superb work with a number of DIY-feasible

lasers and has published fine Web pages about them; and

to Sam Goldwasser, for his amazing Laser FAQ. (Links,

below.) If I have left anyone out, I hope they will

forgive me...

===============================================

Alfon also has

a number of YouTube videos

showing some of his lasers in operation.

[Although it is somewhat peripheral, you may want to read

my rant about the explanation that is in the Scientific

American “Amateur Scientist” nitrogen laser project.

— There are some potentially useful references at the end.]

===============================================

Sam’s Laser FAQ

is an incredible resource, covering a tremendous variety

of laser types. My one caveat is that in addition to a

lot of important information there are many opinions,

some of which are more credible than others. When you

see descriptions of a laser or a project, or

specifications of a commercial device, they are

generally quite reliable; when you see someone stating

that dye lasers are not worth the trouble (because he

barely managed to threshold Rhodamine 6G with 200 joules

into his flashlamp), that’s not necessarily as

reliable. (It is entirely possible to threshold some

dyes

with just a few joules into a flashlamp,

but it is extremely difficult to threshold R6G or any

other dye if you drive your flashlamp with capacitors

that are not well adapted to fast-pulse service. This

clearly includes photoflash capacitors, though they are

admirably suited to slow pulse service.)

===============================================

Here is a page

on which I hope to provide additional technical

information about TEA nitrogen lasers, the principles on

which they work, circuit topologies, and so on. As of

late 2011 I am just starting to work on it, so please

bear with me if you find it mostly empty. (You can

always email me with questions.)

To the top of the LASERs section

Email: a@b.com, where you can replace a with my first

name (jon, only 3 letters, no “h”) and b

with joss.

Phone: +1 240 604 4495.

Last modified: Thu Sep 13 00:59:08 EDT 2018

Parts and Materials

Construction:

1. The Power Supply

Construction:

2. Parts

Construction:

3. The Laser Itself

Construction:

3A. Assembly

--> CAUTION <--

Signs and Symptoms:

Working and Nonworking TEA Nitrogen Lasers

Continuing Progress:

Improved Performance and Advanced Versions

Alternative Drive Circuits

Glass plate in position

Baseplane in position on the glass

5-mil polyester sheet (the dielectric) on the baseplane

(See remark, just after Figure 40.)

Upper plate of the dumper cap in place

Upper plate of the peaker cap in place

Ground connection in place

Upper side of spark gap, shown in position

Channel electrodes in place

Weights in place

The laser, in operation

Figures 30-39: Assembling a Charge-Transfer version of the laser

Relevant Milestones

Addendum:

Dye Lasers as Indicators of Performance

Acknowledgements

Links

There are various DIY laser projects on the Web, including several TEA nitrogen lasers. No two of these are alike, which underscores the fact that there are lots of ways to think about the requirements and parameters of these lasers.

the Joss Research Institute

19 Main St.

Laurel MD 20707-4303 USA

Contact Information: