I found all of the rotating-disk electrostatic “influence” machines rather difficult to understand, btw, until I wrote my own version of this French page about the Wimshurst machine. In the course of making my translation I found that I needed to describe the action a bit more fully than the original page did, so I added specific notes about what happens when a sector is at various positions, and I also added a section about induction (formerly called influence, which may possibly be a better term). The result is really more of an adaptation than a translation.

The act of writing that adaptation was what really

permitted me to understand the way the machine works,

and I note this because it is something many people have

found: if you want to understand something better, try

explaining it to someone else. This will also let you

know, in a big hurry, just how underappreciated teachers

are in the US (or wherever you are). Technical writing

is also difficult and frustrating; one of the few

compensations is the fact that the writer gets to

understand the material better by documenting it. If the

writer is good (and lucky), other folks also get to

understand it.

Because the Voss machine has only one rotating disk,

there is no reason why its inductors need to be mounted

on a second disk; any flat plate of appropriate size (or

even two flat plates) will do. For convenience, my

machine uses two glass plates, each 6" wide and 15"

tall, spaced 2" apart. This gives me a 1" margin beyond

the edge of the rotating disk, which is about 12"

across. Because my design does not use a second disk,

and because we now have epoxy glue, I actually

don’t think I need as much margin as I have

provided; but it keeps the frame out of the way, and a

bit of extra isn’t likely to hurt anything.

Before we get to the inductors and appropriator brushes

and their mountings, however, there is a crucial issue

to be dealt with: how do you mount a flat disk on a

shaft so that it doesn’t wobble as the shaft

rotates? The general question is compounded here by two

factors, the first of which is that the disk I want to

use is a very old phonograph record, which is probably

made of shellac with various arcane additives, and is

quite brittle. (I know this because I have broken a few

of them...argh.) The second is that the entire device is

going to be exposed to high voltages, and I don’t

want to provide extra paths that might limit the

performance of the machine, so I would like to avoid

materials that are highly conductive. (In fact, I am not

entirely happy about the fact that the main shaft is

made of metal. We’ll just have to see whether that

works out well.) One other important issue: I want to be

able to disassemble the mount, so that I can replace the

disk if I either damage it or decide to try a different

one.

I thought about this for some time, and solicited advice

from various folks. Our Range Safety Officer, Lisa

Peoples, suggested a 3-piece collet with a retaining

ring, and after I thought about that for a little while

I decided that it was a fine notion. (I’d been

thinking about structures to hold the disk; she, on the

other hand, was thinking about structures to hold the

shaft. I mention this as a reminder of how

important it is to keep all of the options open, and to

avoid getting stuck inside a box that is smaller than

the actual problem.) I modified her original suggestion

to use two pieces instead of three, which makes it

easier to build, and then modified it again to maintain

the alignment of the pieces, because I want the disk to

be pressed against a [cushioned] flat surface. What I

eventually decided on is shown in the photos below. It

is not by any means original — you can see similar

mountings on old water-wheels and in various other

places.

The disk is decently flat (I chose it from among a

rather large number that I purchased at the Friends

of the Library Book Sale), so it should be reasonably

straightforward to trim out the [inevitable] wobble; but

because it is so delicate, I have strengthened the face

that the wobble-adjusting screws will press against by

gluing a piece of phenolic circuitboard material onto it.

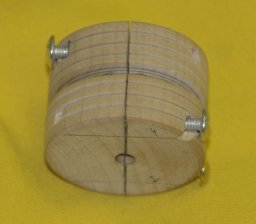

Here are some preliminary photos of the wobble adjuster,

the collet, and the pressure plate on the disk. The

metal screws in the collet were temporary; I have since

replaced them with nylon ones.

If you decide that you want to build a Voss or other

static generator, there is no reason why you need to do

it the same way I did; that said, however, some people

may want a bit more information about the collet,

because it seems to be a decent way to hold the disk in

place. I made it from two small wooden wheels that I

bought at a hobby shop. (These typically come in

packages of 4, which is handy.) Here is one of the

wheels:

The back side is flat and very plain.

I slid two of these onto the shaft with their flat

sides apart for maximum stability, and used J-B Weld

epoxy to glue them together. That gave me a disk of

double thickness, prealigned to the shaft. Here is a

cross-section:

(I did not take photos as I was doing all of this, so I

was obliged to make these illustrations from the completed

piece.)

Then I drew a line across one face of the disk, through

the center hole (the horizontal line that separates the

two pieces, though I did not saw them apart

at that point), and two more lines, to indicate the

positions of the screw holes, at right angles to the

first one:

Then I drilled 4 holes into the wheels, so that they

were in wood all the way through, and some distance away

from the shaft, using the lines as guides. You can see

the holes in the cross-section, above, and here:

Originally, these holes were all the correct diameter

for a tapped 8-32 hole. After I drilled them I sawed

through the middle of the collet, which gave me two

halves, each of which had 4 holes in it. Then I drilled

out 4 of the holes to the body size of the 8-32 screw,

and tapped the other 4. I built this collet with two

screws facing up and two facing down, but I doubt that

it makes any real difference.

(10 July, 2007)

I noticed that the screws were bending when I tightened

them, so I went back to the bandsaw and created flat

places for the heads to rest on. Here are two views of

the modified collet:

(06 July, 2007)

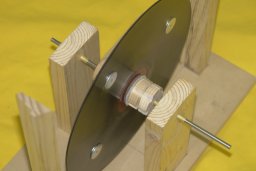

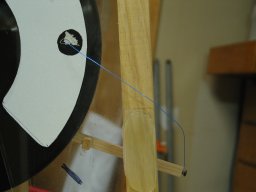

Here is the assembly, static and rotating, though not

yet in its actual bearings. You can see that there is

little or no wobble as the disk rotates. (The blurry

dark-gray vertical line in these two photos is the

phonograph record, which you are seeing edge-on.)

The small wooden wheel at the left is from an earlier

version of the design; I decided to use wheels of the

next larger size, both for better angular control and

because they have center holes of the correct size

to fit the shaft, and I don’t have to drill them

out.

As you can see, this setup appears to work decently

well. I trimmed out the wobble, and took the opportunity

to sand the edge of the disk with the handy Dremel tool,

so that it doesn’t move in and out quite so much

when the disk rotates. (The hole in the middle of the

disk is fairly well centered on the hole in the middle

of the pressure plate, but at least originally it was

not as nicely centered on the disk itself.)

The “front” of the disk, the side the

sectors will be on, is the one that faces to the right

in these photos. The inductors will be on glass plates

to the left of center, which is to say behind the disk.

My next step is to mount the shaft in its bearings on

stands that hold it up from the base. Then I need to

mount the glass plates on the base, trim them so that

they are parallel to the disk, and position the

inductors correctly on them.

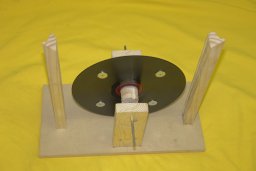

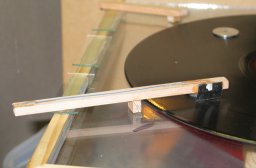

Here is an extremely tentative partial layout, with

the shaft simply inserted in holes in the vertical

posts; the bearings are not yet mounted.

We are viewing this from the other side: the front of

the machine, with sectors and combs and brushes, is to

your left; and the rear, where the drive pulley will

eventually be, is to the right. The disk (not present in

this photo) goes just to the left of center, and the

glass plates with the inductors on them (also absent)

are just about at the middle. The first drive motor I

intend to try is the small fan motor in the foreground.

It is slightly annoying that the longer end of the shaft

sticks out the front, but there is nothing preventing me

from sawing off the excess, and I will probably do so

later on.

One reason why this is so tentative is the fact that I

do not yet know how large some of the parts will be,

and that makes it difficult for me to decide where to

put the parts I already have. At some point, and I will

reach that point fairly soon, I’m going to grit

my teeth and start positioning things. I will probably

wait until I have the glass plates and their mounting

frame pieces cut, though, because those are crucial.

(09 July, 2007)

I have made the pieces of the frame that will hold

the inductor plates, and I have marked the base to

show where the plates and their frame and the posts

for the shaft will go:

As you can see, the posts for the shaft are warped.

Fortunately, they are fairly symmetric, and I am largely

ignoring the curvature.

I have just constructed a sleeve to use as a front

bearing for the shaft. It would have been nice to buy a

thick-walled tube, but I didn’t find one; I did

luck out, though: I found a tube that the shaft just

barely fit inside, a tube the first tube just barely fit

inside, and a third tube that the second one just barely

fit inside. I have epoxied sections of the three tubes

together to make a tube with a reasonably thick and

strong wall. I have a ball bearing that I am thinking

about using as the rear bearing, but it is very small,

and I’m not sure whether it will handle the forces

involved. I may just cut the sleeve into two pieces; it

is certainly long enough to make more than one bearing

out of.

(11 July, 2007)

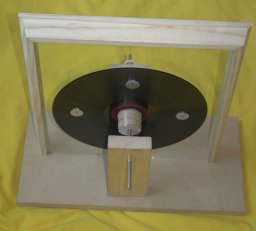

Here is a rather tentative preassembly, with the shaft

present (but not held in position, and possibly with the

disk facing the wrong way):

Having gotten this far, I can tell you that it is

extremely important to allow yourself some “wiggle

room” in all 3 axes. If you fail to do this, you

will almost certainly find that you can’t get the

shaft to rotate easily, and you can’t line up the

disk with the plates that the inductors are on. As

things currently stand I have not allowed myself quite

enough wiggle room, and I am going to have to increase

the amount.

(12 July, 2007)

I have attached the two glass plates to the frame that

holds them, but not to the base: I want to be able to

adjust the tilt if necessary. Here is an overview from

the front, and two details of the back, with everything

more or less in place:

The washer assembly that is visible at the left edge

of the middle photo is my tentative plan for setting

the distance between the disk and the glass plates.

When the machine is fully assembled the metal washer

will be held in place either by a small collet or

perhaps, for simplicity, by two cable ties wrapped

around the shaft. (Two instead of one because the

heads are wider than the tongues. It would probably

be best, actually, to use three.)

It appears that the tilt issue is not going to be much

of a problem; I expect to deal with it by putting a thin

shim under the front shaft post. My main concern now is

the fact that if I position the disk close to the glass,

the phenolic pressure plate scrapes. There are three

obvious possible solutions:

(The results are visible in the photos where I show the

inductors, below.)

In the course of assembling the frame, I found that

the crosspiece at the top was a bit too long. I went

back to the miter box and sawed the end off. It was

still too long, but only by a very small amount, so

I sawed the end off again. Here are two views of the

resulting chip; notice how nice and smooth the cut

surface is:

The chip is thin enough that it is quite translucent:

The inductors are crucial to the operation of the Voss

machine. They are usually paper, often with a metallic

strip underneath to help compensate for changes in the

conductivity of the paper with humidity, but occasional

machines have inductors made from metal foil. I have

made mine from Origami paper, of a particular type that

has foil on one side, as this obviates the necessity for

separate foil strips. The inductors are connected to the

appropriator brushes, which (as I have already

mentioned) contact the raised bosses on the sectors.

I thought about how to put the inductors on the back

sides of the glass plates, and eventually decided to

use the following procedure, while wearing thin

disposable gloves:

This may work. (I saw a bit of looseness

developing along some of the edges and at one corner, so

I dripped a bit of alcohol on the overspray shellac

around the edge in those areas and worked it around;

they appear to be settling in. Frankly, as long as the

inductors are fairly flat and mostly touching the glass,

it may not be an issue: electrostatic attraction is

likely to hold them in place during operation.)

(Note, added the following evening: looks like

it’s stable, so I’m going to call it

a viable method.)

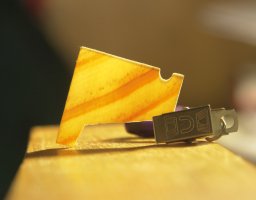

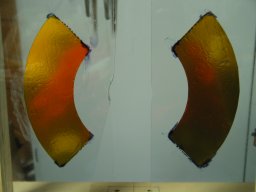

Here are photos of the inductors, in place. The

picture on the left was taken from the front,

and the one on the right was taken from behind.

You can see where I have carved away a small amount

of glass, in the middle, to make a larger space for

the pressure plate on the back of the rotating disk.

(16 July, 2007)

I need to be able to make contact with the foil, but

that side of the paper is stuck to the glass.

Carbon-based ink (Sumi ink or India ink, for example) is

known to be conductive enough to serve as the sector

material, but would it soak through the paper enough to

let me contact the foil? I took a small circle of the

same kind of origami paper the inductors are made from,

and painted Sumi ink on the back. After it dried I

scraped a bit of the anodized surface off the foil side

so I could touch actual metal with the probe of my

meter, and was very happy to discover that the answer is

a clear “Yes.”

Then I thought about the fact that the disk may end up

rotating either way, depending on whether I’m

turning it by hand or with the motor, and that means I

have to be able to swap the positions of the

appropriators and neutralizers. Usually, each

appropriator structure is built at the correct end of

the inductor it’s in front of, and makes contact

there; but (particularly in the case of metal-foil

inductors) there is no earthly reason why it has to be

that way, so I made my Sumi-ink dots at the outer edge

of each inductor, halfway up. We’ll see how well

that works when I get to the point of testing the

machine.

The neutralizer, the collector combs, and the

appropriator brushes all move charge to and from the

disk surface.

The neutralizer is a pair of combs, connected to each

other by a wire or bar, that sweep the disk surface and

remove charge of one sign so that the surface can be

recharged with the opposite sign as it passes in front

of the other inductor. These combs include brushes to

contact the sectors, which hold significant amounts of

charge.

The appropriator brushes, which are connected to the

inductors, must also make physical contact with the

sectors. In order to prevent the appropriators from

being in contact with the disk all the time, the sectors

(or at least small contact points in their middles) are

raised up from the disk. Sometimes metal balls are used

for this purpose, and I may eventually go that route,

but for my first try I am just using metal washers that

are about 1 mm thick. These are wide enough that they

will probably serve as sectors themselves.

This introduces an additional constraint or two; first,

the wobble needs to be smaller than the thickness of the

sectors (or the bosses that protrude from them), as

otherwise the brushes either fail to make contact with

some sectors, or are in contact with other parts of the

disk surface. So far, I do not have any bosses on the

sectors, which are rather thin, so I have to eliminate

as much of the wobble as I possibly can. Second, to

whatever extent the sectors or bosses stand proud of the

surface, parts of the collector and neutralizer combs

must also be positioned sufficiently far above the

surface to avoid collisions.

I want to use rather sharp needles in my combs, as that

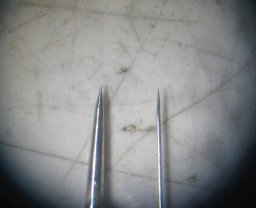

gives better collection efficiency. Here is a photo

showing an “appliqué sharp” sewing

needle (upper) and an acupuncture needle (lower), viewed

through a low-power microscope:

Usually, only acupuncturists can get acupuncture

needles. I managed to get my hands on one for long

enough to take this photo, but I will be using sewing

needles for the combs on my machine unless I luck out at

a garage sale or something. (I suppose I could sharpen

the sewing needles; but I am going to need about 4

dozen, and I’m not willing to spend the time it

would take unless I am very sure that the results will

be worth it.) It is definitely possible, btw, to

sharpen one of these things. Here is the same sewing

needle (upper) after I chucked it into the Dremel and

rubbed it on one of my favorite ultrafine abrasives,

compared to the same acupuncture needle (lower) —

(Sorry about the focus.)

Here’s the abrasive, a brown ceramic integrated

circuit package (left). The purple (right) and white

ones and most gray ones are too coarse for this, though

I do use them for sharpening calligraphic pen nibs,

which I then polish with the brown ones...

To whatever extent I can optimize charge collection it

seems pointless to lose it to corona, and I plan on

surrounding the needles (except, of course, the region

directly in front of them) with a structure intended to

minimize losses. Wood turns out to be a vaguely

semiconducting material, and is very good for equalizing

field contours and thus performing this function. I

expect to build the brushes and combs of this machine

from it, and I will include photographs as I construct

those parts. In the meanwhile, you can find out more

about this use of wood by reading the description of

Winter’s machine at the beginning of Homemade

Lightning, by R. A. Ford.

A typical Voss machine (as on the Kenyon page I link to

above) has 6 sectors, but I am initially using only 4 on

this device, for ease of construction. The sectors are

present partly to get the machine to self-start, and

partly to charge the inductors; the surface of the disk

(at least, the part that is in front of the inductors)

is the primary charge-carrying region. In this regard,

the Voss machine is somewhat like a hybrid between the

Wimshurst (which uses its sectors as charge-carriers)

and the Bonetti (which uses an area of the disk’s

surface as its main charge-carrier, and lacks sectors).

(16 July, 2007)

I don’t really need anything fancy for a first

test, so last night I put a sewing pin under the

microscope, next to the appliqué sharp needle.

To my surprise, I found that the points were quite

similar in size, though the barrel of the pin is

thicker. Clearly, pins will do for a first test, so I

took my Dremel and a #67 drillbit, and made 4 combs.

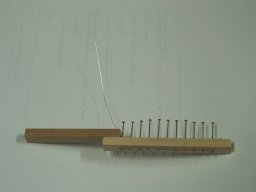

Here are two of them:

The pins are 1/4" apart, and there is 1/2" of clear

space at each end. There are 11 pins in each comb.

I made these by pushing the pins too far through the

wooden bar and then pressing the bar down onto two

pieces of glass about 3" apart on the bench, with a

washer in the middle of the space between them. (You

will notice that the 5 points in the middle do not stick

out as far as the 3 on each end. This is so they

won’t collide with the sectors if I position the

combs very close to the disk.) Once everything was

positioned nicely, I put a dot of cyanoacrylate glue

around the place where each pin went into the wood. I

will probably just use thin wire to connect to these;

there isn’t really any reason to get fancy about

it at this stage. The “real thing” will be

entirely encased in wood in any case (except for the

points of the needles), and thin wire will work just

fine. The current involved here is measured in

microamperes, after all.

Two of the combs need to have brushes added to them so

they can serve as neutralizers. I am thinking about

using some very thin metallized Mylar™ for this,

as I happen to have a scrap of it here.

If I can figure out how to position these things,

it won’t be long before I make a preliminary

test.

(19 July, 2007)

Here are views of some of the bits, as constructed

and in place. The machine is lying on its back,

which accounts for the screwy angle. The handle is

exactly what it looks like (a window crank), but I

have adapted it by gluing a brass tube into it with

J-B Weld epoxy.

(Those last two were taken while the epoxy was

still wet.)

Here are two of the back side, showing the way I am

connecting the inductors to the appropriator brushes:

Note that these are all temporary, for testing.

The wooden bars are stuck to the microscope

slides with RTV, and can easily be removed.

One important thing to remember: this machine is set up

for clockwise rotation of the disk. As the

sectors begin to pass in front of the inductors they

pass under the appropriator brushes, and then as they

begin to move away from the inductors they pass under

the neutralizer brush/combs.

(evening of 19 July, 2007)

I tried running the machine, to no avail. I tried

starting it with a piece of PVC pipe that I had rubbed

with paper, but that didn’t work; I even tried

connecting the appropriators (and thus the inductors)

across the output of the little Wimshurst machine that

I’ve been running my TEA nitrogen laser with.

Still nothing. It behaves as if somewhere, somehow,

charge is leaking fairly rapidly and preventing the

machine from doing what it should. I have already

checked a fragment of another similar disk with the

Wimshurst, and it did not leak, so I doubt that the disk

is the issue, but I will be checking it with the

Wimshurst anyway, to be sure. (I did. It wasn’t.)

(Early morning, 21 July, 2007)

I smell ozone.

Two things (at least) are going on here. First: in the

process of checking the appropriators and inductors, I

discovered that the ink spot on the back of one of the

inductors was not really making decent contact with the

metal foil on the front. I took an X-Acto® knife and

carved a tiny bit of paper away from the foil of the

inductor at the outer edge, near the ink spot. Then I

smeared silver conductive adhesive on the scrape and

over to the ink spot. End of that problem. For

obvious reasons, I then repeated this with the other

inductor.

Second: it turns out that metallized Mylar probably

isn’t the absolute best material to make the

brushes out of. I discovered this by verifying

correct conductivity everywhere else, and then

finally putting one of the meter probes on one

of the sectors, which was in contact with a brush.

Nada. Open circuit.

I ended up putting silver conductive paint on all four

brushes, several times, after which I finally began to

see some charging. I can smell ozone, and if I hold my

finger near the disk while I rotate it, I get tiny

shocks. It’s a Voss machine! Now I have to give it

some output combs and see whether I can get reasonable

performance out of it. (The RTV is setting, and I

should be able to do more testing during the day.)

(some hours later)

Here is a photo of the machine with the collector combs

in place:

(Sorry that’s a bit fuzzy — it was a

longish hand-held exposure.)

With the combs in place, I was (just barely) able to use

the machine to operate a TEA nitrogen laser, which was

the original design intention. I suspect that things

will be easier with “final” brushes and

combs instead of the temporary versions I’m

currently using, and with a motor drive instead of hand

cranking. Things will also be easier when I find a

better material to make the brushes out of. I will

probably be testing some possibilities as my next

step, unless I just decide to build a new machine.

(I have a glass disk that is 4 mm thick and 50 cm

across...)

(04 August, 2007)

Well, I had a disk like that. Turns out that

it was was tempered, so when the glass shop tried to

drill a hole in it, it turned into many tiny pieces.

They are going to make me another one, 20" across,

3/16" thick, and with a 3/4" hole in the middle.

In the meanwhile, I have acquired some acupuncture

needles. These are 0.12mm diameter (as thin as

I’ve seen so far), and impressively sharp.

Here is my specially sharpened “appliqué

sharp” sewing needle, next to one of them:

I am constructing new combs with these needles, to

see whether I can improve the operation of the machine

before I build a larger one. Here are some early stages:

I am planning on covering the tops of the cutoff

needles with another piece of wood, and I hope to

connect to this array with wire that is insulated

for 40 kV.

Here are the motor I expect to use, and its pulley:

The motor comes from a small ventilation fan or

humidifier, acquired at a local thrift store. The pulley

is a small one, removed from a little sheave that I got

at the hardware store. I drilled it out so it would fit

onto the motor shaft, and cleaned it up slightly so that

it is fairly well balanced. It is held onto the shaft

with J-B Weld epoxy.

I am still thinking about the shaft pulley on the

machine, and how to attach it. (More about this later,

as it begins to take shape.)

(13 August, 2007)

I have built a new set of brushes and combs for this

machine, using 0.012mm acupuncture needles for the

combs. Brushes and combs are encased in wood. (I will

take photos as time permits.) I tried this setup with a

second phonograph record, and was not satisfied, so I

bought a piece 0.093" Lexan™ (polycarbonate);

marked a 12" circle on it by tracing around a phono

record; cut out the circle with a scroll saw and filed

the edge a bit to smooth it; attached 6 washers for

sectors; and installed it. A Neoprene™ washer

(1/4" hole, 2" diameter) replaces the hard white foam

and cork composition circle that I was using between the

original disks and the collet. The pressure plate for

this disk is the one that I made for the second phono

record; it is cut from a plastic cap that originally

graced a spice jar. (Again, photos later.)

There is no guarantee that this will work well, but I

should note that when I removed the plastic protective

sheet from the front of the disk it took on a nice

static charge, which certainly bodes well. I have not

bothered to remove the sheet from the back of the disk;

I doubt that it makes any real difference. (If I change

my mind later, I will probably be able to remove it

without destroying the setup.) I should note that this

new disk is not flat, and also that it is considerably

more flexible than the phonograph records were. I

don’t think wobble will be a huge issue, but the

center of the disk bulges out (toward the front of the

machine). This may worsen as the disk becomes charged

and is attracted to the inductors... We Shall See.

As I write this, on the evening of August 13th, the RTV

(aquarium caulk, in this case) is still curing. I hope

to be able to test the machine later in the evening, but

it may have to wait until morning. I will report the

results if they are worth reporting.

(14 August, 2007)

While I am having a bit of trouble with the brushes

and the bearings, this unmistakeably works. I ran a

small TEA nitrogen laser with it, as a test. It is

slower than the commercial Wimshurst machine that I

normally use for that purpose, perhaps partly because

it has only one active disk. There may also be issues

with conductivity inside the neutralizers. Either way,

it is obvious that polycarbonate is viable as a disk

material, though it is not as stiff as I’d like.

(08 August, 2007)

In a paper that is available on the Web,

Noël Félici

offers some interesting insights on charge transfer.

Our machines operate in what he calls “Low

Mobility” mode. Under somewhat different

circumstances, it becomes possible to transfer

considerably more charge. Félici was granted

several patents for his work; his machines produced

as much as ~2 W/cm2, with maximum power

outputs ranging as high as kilowatts (!).

I would like to investigate the low end of high

mobility (as it were), and I hope to rebuild this

machine in a way that will permit me to do so.

First, however, I am going to replace the original

disk with another, because something is wrong now

and the machine isn’t working. As long as

I’m doing that I will also be replacing the

brushes and combs with new ones of a different

design, to see whether I get good performance.

Once I’m reasonably satisfied (or the machine

fails again and I conclude that phonograph records

of the type I’m using are poor candidates),

I will begin to think about a glass disk and more

stringent conditions. I will continue to post as

things proceed.

(16 August, 2007)

I bought a sheet of Lexan™ (polycarbonate),

12"x24", 0.093" thick, and made a disk from it.

This clearly works, but I am still having some

trouble with brushes and combs. I conclude that

Litz wire is suboptimal for brushes, as it tends

to be hard to strip (tiny wires with plastic coating,

unless you can get ancient stuff with varnish/lacquer

instead) and not springy enough.

Even so, I have been able to power my little TEA

nitrogen laser with this disk, and I am once again

thinking about motorizing this machine.

The best source of information about the Voss machine

(and other electrostatic machines) on the Web that I am

currently aware of is

a set of pages by Professor Antonio Carlos M. de Queiroz.

There are occasionally issues with the server, so if you

cannot see these pages the first time you try, wait a

while and try again. They are well worth it: there is a

huge amount of information on them and in the links that

Professor de Queiroz provides, and he has built a wide

variety of extremely good electrostatic machines himself.

My email address is a@b.com, where a is my first name

(just jon, only 3 letters, no “h”), and b is joss.

My phone number is +1 240 604 4495.

Last modified: Thu Jun 23 16:04:29 CDT 2016

Sidebar: Construction of the Collet

Sidebar: Why We Love Japanese Saws

The Inductors and their Mounting

Brushes and Combs

Motor Drive System

Continuing Development

Future Directions

the Joss Research Institute

19 Main Street

Laurel MD 20707-4303 USA

Contact Information: