(15 August, 2006, ff)

This page details the construction of a nitrogen laser that is a follow-on to the “DKDIY”design I published here a few months ago, along with a “How-To” page. Because this material is being written substantially as a historical track of the project as it is taking place, it is not necessarily organized logically. When the design is fully stabilized I will try to provide a “How-To” page for those who want to build a laser of this type.

(Note, 2006 September 27: Between the “DKDIY” laser and this “DK-Plus” laser, I experimented with a larger design, which operated, but not at the performance level I had expected. This appears to have been caused by several factors, some of which I may explore [and, I hope, correct] by returning to that laser and rebuilding it, now that I have this one working well.)

(Note, 05 October, 2009: I am reworking this laser, and I hope to get somewhat better performance from it than I originally did. There are a number of issues involved in the rework, which I discuss at one or two places on this page, and in a second page specifically devoted to it.)

I would strongly suggest that you read through at least

the early sections of this page and all of the following

page before you attempt to build one of these, as that

will help you avoid some “gotchas” that I

encountered.

This laser uses high voltages, and capacitors that can

store lethal amounts of energy. It puts out an invisible

ultraviolet beam that can damage your eyes and skin. It

is important to take adequate safety precautions and use

appropriate safety equipment with any laser; but it is

crucially important with lasers that involve high

voltages and/or produce invisible beams!

The first version of this laser was intended to provide performance at least as good as that of the classic Scientific American “Amateur Scientist” nitrogen laser design, but using “doorknob” capacitors instead of circuit board, and with a triggered spark gap as a switch, rather than a free-running gap. It is a “Voltage Doubler” circuit, often mistakenly called a Blumlein. I chose the doubler circuit because it is relatively easy to construct, and because it parallels the circuit of the SciAm design.

That first “DKDIY” laser used a dozen laser-grade SrTiO3 doorknob capacitors. It reached threshold at about 12.4 kV, and developed a little over 100 kW at about 20 kV. The channel was 22 mm across and about 45 cm long, and the electrodes were pieces of extruded aluminum carpet edging.

This revised version will use 16 doorknobs, and will have electrodes a bit more than 80 cm long, with capacitors along the middle 45 cm or so. I originally intended to use a piece of brass shim stock as the cathode; shim stock has a fairly sharp edge and so should provide some preionization by generating corona early in the discharge cycle. It’s a bit thin in comparison with the anode, but may work. If not, I can always try a packed-blade cathode, or add some extra preionization.

(Note, added later: I soon abandoned the idea of a thin sharp-edged cathode, and shifted to two identical electrodes.)

My original intention for this enlarged version was to use carpet edging again, at least for the anode; but when I examined the pieces I had on hand I discovered that they were not very straight. Straightness being a real issue, I changed my mind and turned to something that does have a straight edge: an aluminum ruler. The ones I’m using were originally 4 feet long, but I have cut them down to 32 inches, a reasonable length for this head. They are 2" wide, which fits well, and 1/8" (~3.25 mm) thick, also very reasonable, though that is significantly thicker than the previous electrodes, which had a cylindrical edge only 1.5 or 2 mm in diameter. My hope is that the capacitors I’ve added will be enough to let me pump the additional channel volume. (It is important to deposit sufficient energy into the discharge, in order to be sure that the laser will operate well above threshold. Typical high-performance nitrogen lasers seem to dissipate at least 40 joules per liter of active discharge, and some exceed 100 j/l.)

Following an idea developed by Jarrod S. Kinsey, I am constructing the sidewalls and spacers of this new head from wood, a construction material that is widely available, extremely tractable, and relatively inexpensive. (I may provide windows through the sidewalls to permit observation of the discharge in the channel.) Wood tends to be slightly conductive at high voltages, but I will be using walls that are varnished, which should reduce the conductivity somewhat. If some conductivity remains, there is a small chance that it may provide a bit of preionization, in much the same way that a semiconductor plate does.

(Addendum, 27 September, 2009)

Most wood is a bit porous, which is a problem. (It turned out to be a problem even with the varnished yardsticks I used in the head of this laser.) Consider a nitrogen laser running at 50 Torr; if there is a leak that admits 2 Torr of air, the gas mix contains more than 3/4 of 1% oxygen, which is too much for optimal performance. (A small amount of oxygen is okay, and in fact at roughly 1/3 of a percent you may see slight improvement in performance. Beyond about half a percent, however, oxygen degrades the performance of the laser.)

If you use wood, make sure that you either coat the interior surfaces with something that is relatively impervious to air, or soak the wood in something that will solidify and make it impervious. One way to do this is to mix epoxy with isopropyl alcohol (at least 91% pure; 99% pure is better), and brush it on. You probably want the epoxy to be just liquid enough that it brushes reasonably easily; if it is too dilute it has a tendency either to fail to cure, or to cure to a soft and rubbery condition. After the first coat of epoxy has had time to cure, repeat the process until it no longer soaks in; this will almost certainly take several coats. When all of the epoxy has fully cured, the wood should be sealed well enough to be usable.

There are certainly other ways to accomplish this, but

you will want to think it through carefully. Some

paints, for example, continue to emit solvent vapors for

months. These may (or may not) interfere with lasing.

There is only one real way to find out; and if the

answer is ‘yes’ you will probably be obliged

to rebuild the head, which is (believe me) a real annoyance.

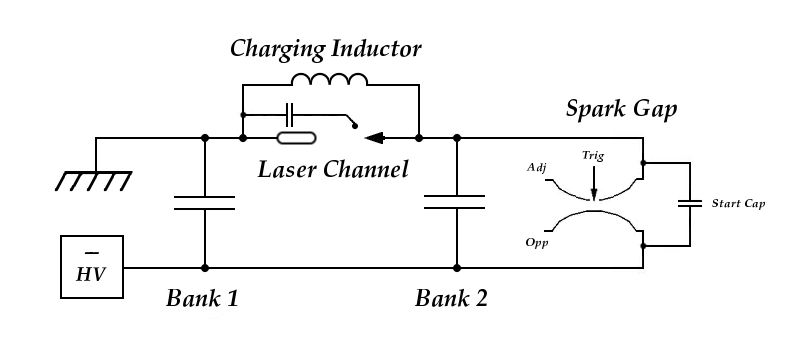

Here is the circuit diagram of the laser:

The capacitor labelled “Start Cap” is present mostly in order to produce a current of a few dozen Amperes in the spark gap very quickly when it is triggered, to help develop a substantial conduction channel in it. The manufacturer recommends pushing at least 10 Amperes through the gap to get it to switch properly. This probably takes only a few dozen pf, which can be furnished by a rather small doorknob; it is, though, important to keep the connections fairly short and the inductance down, as you have only a brief time in which to accomplish the job: a good spark gap should switch in a few tens of nsec. (Please note that although it is possible to make subnanosecond spark gaps, the designs I’ve seen were pressurized to about 1500 psi and were built into cylindrical transmission lines.)

I have shown a charging inductor across the channel, but a charging resistor works better in some designs, and I will probably try both to see which is appropriate for this laser. I have also shown a small capacitor that connects to a dot near the cathode. The dot represents a thin wire that is strung along the entire length of the head, and serves to preionize the laser. This is discussed in the text, and is the initial configuration I’ve chosen to try; I may move to a different preionization method later.

(Note, added much later: I did. See below.)

The sidewalls of the channel are wooden yardsticks, about 1.5" wide and just over 34.5" long, cut down from their original length of 36". I have widened the lower sidewall by gluing smaller pieces of wood to its edges, as it was just a bit too narrow to work well — I want to have the electrodes 25 mm apart, and I need to have room to attach spacers to separate the electrodes from the sidewalls so the discharge doesn’t track along the surface. (At the bottom of the left photo below you can see the 1" spacer sitting on one of the rulers, before I added extra wood at its edges. You may be able to tell that the spacers, which are visible in the photo on the right, are farther apart than they could have been with the unmodified ruler.)

The electrodes are 32" long, but the capacitors are restricted to the center 23" or so. This should help avoid sparking at the ends of the electrodes, where the longer current path provides higher inductance. We hope. [[NOTE: As of 19 August, 2006 I am revising my thinking about this, and moving toward a slightly different head design. See below.]]

Here is a photo showing the underside of the roof, with one of the gas ports visible near its left end; the bottom wall of the channel, with its spacers to position the anode and cathode; and the left end of the anode.

I have to decide, very soon, whether I expect to run this laser under vacuum. If so, I will need to coat the inner surfaces of the wood with something, to reduce outgassing. If I’m only going to use atmospheric pressure helium with a small amount of nitrogen, on the other hand (as I did originally), I don’t think I will worry about that. The rulers are already varnished or coated in some manner, and the other bits of wood I’m using are fairly small. I am tending to think that atmospheric pressure may be a good bet, as I am not sure how well the rulers, which are of low quality, would stand up to vacuum and its attendant stresses.

(Note, added much later: they stand up just fine to

the stress, but they leak unless carefully sealed.)

(19 August, 2006)

As I continue to think about this laser, I am changing

my mind about how to proceed with it. (This should come

as no surprise to anyone.) The base design takes a

replaceable head, and I have at least three ideas for

heads. The one I now think I will build first has 1/8"

thick aluminum rulers as both electrodes. These will be

separated by 5/8", just under 16 mm (I did a rough

calculation last night that suggests better chances of

good performance with tighter spacing than I used in the

original DKDIY laser), and will be about 35" long, to

help prevent sparks at the ends. Because of the

narrower channel, the rows of capacitors will end up

being 4" apart instead of 4.5"; I will probably put the

“lower” row 1.5" upscreen, rather than at

the 1" position shown in the diagram.

I am becoming more and more convinced that preionization

is the key to high performance in low-pressure nitrogen

lasers (in TEA lasers, it appears to be essentially

mandatory), so I am also going to add a preionizer, a

thin nichrome wire in the first version. I intend to

attach the upper sidewall in such a manner that it is

easily removed. That will let me test other

preionization methods without totally rebuilding the

head.

My rationale is that this head will be extremely easy

to construct, and should swiftly provide some much-needed

information about preionization methods. It should also

work well, assuming I can preionize it sufficiently.

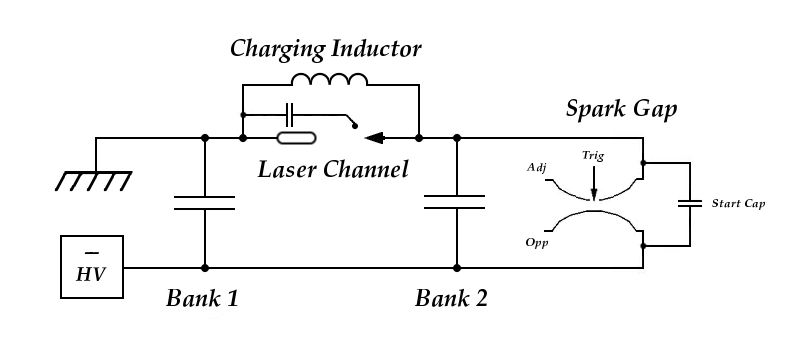

Here is the tentative layout of the laser, based on an

8" x 34" brass kickplate I acquired at the hardware store:

The asymmetry, with wider open area “above”

the “upper” row of capacitors (in case the

print in the picture is too small to read) facilitates

making connections to the spark gap, which is not shown

in this diagram.

I also acquired some square extruded aluminum tubing to go

under the baseplate to stiffen it — the head is long,

and probably not stiff enough by itself to force everything

to stay lined up.

The aluminum rulers I’m using for electrodes are

just 2" wide, and the spacing between them is 5/8",

which sets the spacing between the rows of capacitors

— I have to be able to bolt the electrodes to

them. Very fortunately, that spacing just accommodates

the wooden rulers I am using for sidewalls with a wee

bit of “wiggle room”, as they are 1 &

7/16" across. If it had been any closer, I would have

had to widen the laser channel or adopt a different

design.

For preionization by wire, there are two obvious modes:

passive, and active. I have discussed these on

the root page of this series, but it’s easy

enough to do a brief review here.

Passive: You typically use a single wire for

this. It is strung along the channel, typically off to

one side so it isn’t in the middle of the

discharge (though people have actually used wires spang

in the middle), and usually considerably closer to one

electrode than the other. You connect the wire through a

capacitor to the more distant electrode. When you fire

the laser, the rapidly-rising voltage across the channel

appears on the wire (the little cap is uncharged, and

essentially looks, at least for a brief period, like a

dead short), and a corona discharge develops. This

provides ions and UV, which preionize the channel.

There are two modes of thought about positioning and

connecting the wire. One says that you should put the

wire close to the cathode and connect the small

capacitor to the anode, because you want your

preionization to be at the cathode. The other says that

the cathode emits electrons, so you should put the wire

close to the anode and connect the little capacitor to

the cathode, which makes the preionizing wire

effectively be the cathode at the beginning of the

discharge cycle. I think I fall into the former category

(wire near the cathode, capacitor to the anode), but I

have not made any study of this, so you are advised not

to trust my opinion. On the other hand, that is the

configuration I am building for the initial tests of

this head.

An alternative that doesn’t involve wires or

capacitors is to use a sheet of semiconductor, off to

one or both sides of the discharge. The conductivity of

the semiconductor has to be chosen moderately carefully,

but this technique (which was developed with CO2

lasers, works quite well. I have made one of these by

putting a thin coating of epoxy onto a sidewall, and

applying fairly fine silicon carbide abrasive grit to it

while it was still wet. I also left an empty channel

somewhere in the middle of the wall, so that sparks

could jump from one semiconductor “electrode”

to the other, but I doubt that this is necessary. On the

other hand, it could provide an easy way of compensating

for semiconductor material that’s a bit too

conductive.

Important note: passive preionization steals energy

from the main discharge. If you don’t steal enough,

you don’t get adequate preionization. If you steal

too much, the main discharge doesn’t get enough.

Either way, performance suffers.

Active: You can do this with one or two wires.

Active preionization requires a separate power supply,

and draws about 1 mA of current, either between one wire

(or two, if you can make sure they both source current)

and one of the electrodes, or between two wires placed

at either side of the channel so that the corona

discharge crosses through the channel.

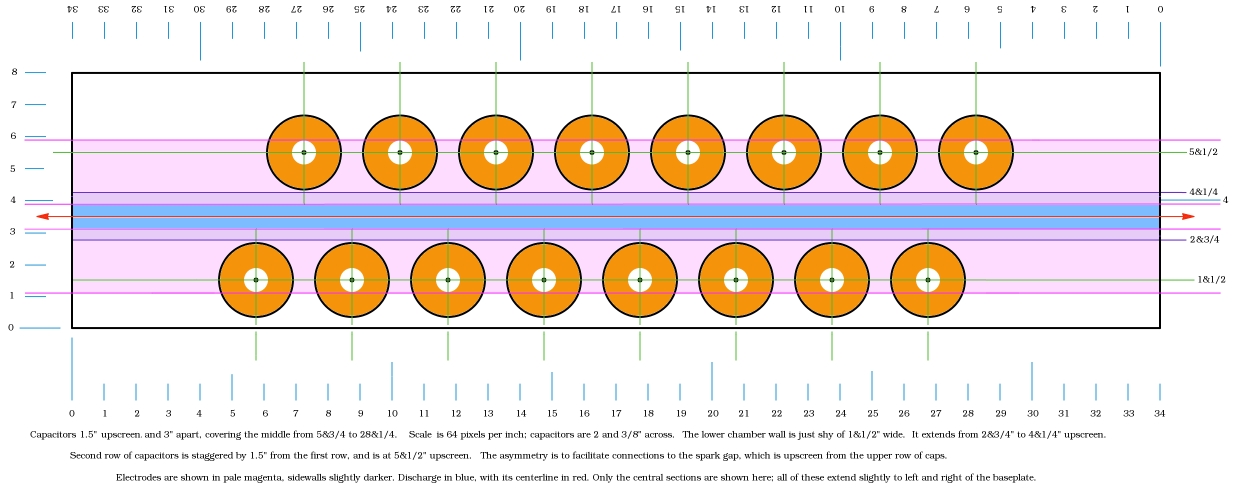

An oil-burner ignition transformer is a convenient

source of high voltage (this technique tends to require

only about 5-10 kV). If your oil-burner transformer has

a centertapped secondary winding with the centertap

connected to the case, the obvious circuit is a bipolar

full-wave rectifier, similar to what you might build for

a low-voltage bipolar supply. Most neon-sign transformers

are constructed the same way, and a small one could be

used for this. Here’s the circuit:

Because this has two outputs, it suits itself well to

the use of two wires.

In use, we would like to forget about the ground

connection, but it is important to be careful because

one side of the HV supply for the laser is also

grounded. I am guessing that if you put a large

resistance to ground from the centertap of the

transformer, and only moderately large resistors (for

current limiting) to the corona wires, you should be

okay. Remember that all resistors need to be able to

withstand rather high voltages. Remember also that

your HV rectifiers should be able to withstand 6 to

8 times the rated voltage. Here’s the logic:

Granted, this is expensive; but it will save you much grief.

As I mention above, I am going with single-wire passive

preionization for the first version of this laser.

(20 August, 2006)

I have marked and drilled the holes in the electrodes,

and I’ve almost completed the sidewalls.

I had set the electrodes out on the bench with the

spacer between them...

...and was about to RTV the floor of the channel on,

when I realized that after I flipped the resulting

assembly over, I’d be trying to connect to the

doorknob caps through the painted numbers. This was

clearly suboptimal, so I set the floor aside and

configured the roof. (I will have to remove the anodized

coating from the surface anyway, so it isn’t that

big an issue, but I think it will be instructive to have

the numbers visible when the laser is finished.)

Because I intend to use a wire preionizer for this

iteration, I wanted to have a narrow space for the wire

to sit in, down between walls of some sort, to help

prevent the discharge from heading for the wire, which

it might otherwise do. This is a wooden head (much like

my own, argh), so I decided to use two strips of wood; I

pushed the first one into place with a straightedge and

held it while the CA (cyanoacrylate) set. Then I put

pieces of cardboard between it and the second one while

gluing that into place:

The result appears to be a moderately straight groove,

which will probably serve. Now I have to figure out how

to glue a 0.0031"-thick nichrome wire into place in the

bottom of that groove, without covering the wire with

glue. I’m thinking about diluting some epoxy with

isopropyl alcohol, painting a thin layer of it into the

groove, letting the iso evaporate, and then laying the

wire onto the surface of the epoxy layer, which will be

quite thin by that point. Because I don’t need

much physical strength, I don’t have to worry if

the epoxy starts to harden before I get the wire onto

it. In fact that might even help, as the wire would be

less likely to get covered if the epoxy is already a

little stiff.

The real problem with this arrangement is that the wire

is a wee bit too close to the cathode. I should have

used a slightly wider spacer on the cathode side. Such,

however, is life. We’ll see how well it works, or

doesn’t.

Once I have the gas ports and the wire in place, I will

RTV the roof on.

(Early AM, 22 August, 2006)

I have dropped the 3-mil nichrome wire into the groove

I made for it, drilled the holes for the gas ports and

installed the connectors, and RTVed the roof to the head.

If I do this again I may design the thing to make

installing the wire easier, and I may also opt for wire

of larger diameter. Still, it’s an interesting

test, and I have another wooden ruler if I decide that

I need to fall back to semiconductor preionization.

Once the electrodes and the roof of the channel are

firmly attached to each other, I can set them on the

baseplate to check the hole positions. (I don’t

want to drill the baseplate until I’m sure

I’ll be able to assemble the laser.) Then I get

to:

At that point, I think I’ll be ready to start testing.

(24 August, 2006)

Here’s a test of what the machine will look like

when I assemble it:

Notice that there are no end windows on the head yet,

the preionization wire is not connected to anything,

and the spark gap is not present. Several other things

also need to happen before this will be a laser, but

at least we can now get a sense of what it will be

like.

Because the rulers I’m using for electrodes are

anodized, it was necessary to clear the areas where

they are going to connect to the capacitors. I figured

that a wire brush on a Dremel™ or other rotary

tool would do the job, and a test showed that this is

correct:

I have brushed the 16 contact areas for the main caps,

on the undersides of the electrodes, and 2 extra areas

on the top of the anode, one at each end, for pieces of

brass shim that will go to the caps that drive the

preionizing wire. As of now, I am planning to use 760 pf

doorknobs for those, partly because I actually expect

the wood to do some of the work for me.

It seems extremely likely that doorknob caps with

broad terminations have lower inductance (and

are therefore faster) than doorknobs with narrow

terminations. Sometimes, there isn’t much

you can do, but a few types can be improved fairly

easily. Here is a little MuRata 760 pf cap:

You can easily see that although the termination is just

a narrow ring around the #8-32 threaded hole, there is

actually much more metal present. Unfortunately, it is

covered with epoxy. Fortunately, you can do something

about that. First, you get to clean the epoxy off:

Unfortunately, I only have two hands, so I can’t

show you how I hold the knife with one hand and rotate

the capacitor with the other; but I trust you get the

idea.

Here is what the cap looks like when it is thoroughly

clean:

You then use silver-loaded conductive epoxy to put a #14

brass washer (or a 6mm washer, as I discovered when I

ran out of #14s) on the cap. The next photo is just to

give you a sense of size and fit; I have not yet epoxied

the washer on. If you don’t have (or cannot afford)

silver epoxy, don’t worry about it. If you attach

the cap to your circuitry with reasonable pressure, you

will still get good conductivity. Do remember the

washer, though.

The washer is just thick enough to match (more or less)

the height of the original termination, and the hole is

just a bit wider than the ring. Why the manufacturer

didn’t simply make these caps with full-width

terminations, so we wouldn’t have to go through

this idiotic rigmarole, I have no idea.

We now return you to your previously scheduled programming...

(Midnight, 25/26 August, 2006)

I have almost completed the assembly of this head. The

windows are on (though, as you will see in the photos,

the RTV has not yet set on the second one, so it is

still propped into place), and the preionizer is ready

for use.

I have discovered a pleasant thing: an ordinary

hole-punch for paper will (just barely) make a hole in

5-mil brass shim stock that is only a little bit large

for a #10 machine screw. It was even tolerable for the

shims on the preionizer, which currently take #8 screws.

I don’t know how long the device will last in this

service, but it is certainly convenient. Cost me a whole

dollar at an office supply store.

Once all the RTV has set, I may be able to perform some

preliminary testing on this design. I have a GP-70 that

is already mounted on brass shims, and although it

won’t be as fast as a properly mounted gap, it

should give me some sense of whether this design is

viable. Proper operation, however, will want a GP-14B

mounted on much wider pieces of shim, for good tight

coupling and better performance. That should be fairly

easy to arrange, fortunately.

(27 August, 2006)

I have now tested this arrangement, using the GP-70

mentioned above. The device discharges, but does not

lase at charging voltages up to 20 kV.

I have tried a variety of fills and pressures, and I

have tried increasing the drive capacitance on the

preionizer. There are some indications of sparking at

the end of the channel that I can see, and I am now

thinking about retreating to a head with glass walls,

though I may very well use wooden flats as

semiconductors for a preionizer similar to the one I

used on the original DKDIY device. I may also sandpaper

the edges of the electrodes to remove the anodizing

from them.

Another possibility is to try 900-pf capacitors, which

should be somewhat faster than the 2-nf doorknobs that

are currently in place; but they also store less than

half as much energy, and I doubt that the speed increase

would be great enough to compensate — that should

change with the square root of the capacitance, whereas

the energy storage is linear at a given voltage.

Time to sit and think for a while...

(later, that same evening)

...but not for too awful long. I have just started

construction of the new roof for this channel. If

the roof isn’t enough, I can also build a new

floor, but let’s do this one step at a time.

I have some glass bars, about an inch and a half across

and 1/8" thick, but they are only 30" long, and I need

something a lot closer to 36", so I am cutting and

gluing. Clean, straight ends are easy to epoxy if you

are not concerned too much about strength, and in this

particular case I think most of the stress will be

across the bar when I pull vacuum on the head, so

I’m not going to worry about it too much. 1/8" of

glass should be about as strong as 1/4" of wood, and the

wooden roof stood up to the vacuum reasonably well.

I am going to try wooden preionizer bars on this roof,

with silicon carbide grit on them. I will leave 1/4"

separation between the flat wood pieces, and that should

be enough to get good operation. It will also let me look

inside the head and see a little of the discharge, which

will give me some information that is hard to get by

other means.

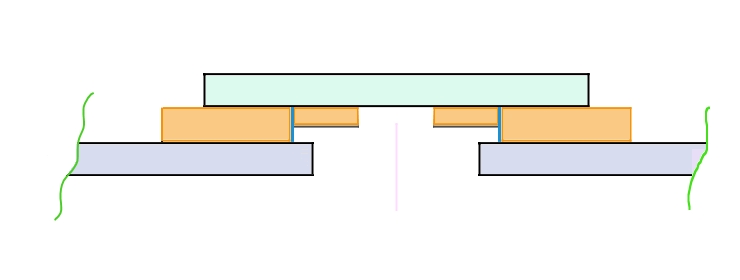

Here is a cross-section of what I am expecting the new

roof to look like:

(Glass is shown in pale blue-green; wood in brown;

electrodes in purplish gray; silver paint in blue;

silicon carbide in gray. The pale pink vertical bar

marks the centerline. The electrode spacing is

unchanged, as is the floor of the channel, which is not

shown in this illustration. Glue and sealant[s] are also

not shown.)

(early evening, 27 August, 2006)

Alternatively, I could dispense with the silver paint

and just put a silicon-carbide-coated strip down the

middle of the open space, possibly 1/2" wide, or maybe

even the full width (3/4"). This would obscure my view

of the discharge, but would probably preionize the

channel adequately.

(early AM, 28 August, 2006)

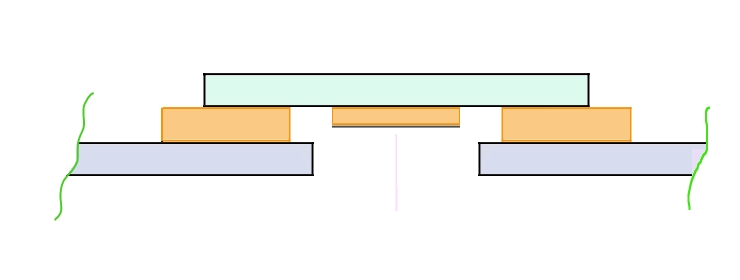

...And that’s exactly what I did. Here is a

diagram:

Here are two photos, one taken with the top sidewall

sitting in place, before I made the preionizer, and

another taken after I put the preionizer in and put RTV

onto the sidewall to seal it and hold it in place:

The wood I had on hand that was the correct width was in

2-foot sections; you can see the joint in the preionizer

somewhat to the left of center in the second photo.

I still need to create the gas ports, but that should

be relatively straightforward. Then I can resume testing.

I should note that while I was setting up the new

“roof”, I also acquired some 1500-grit

sandpaper and removed the anodizing from the upper edges

of both electrodes. I wasn’t able to get the

entire face, but at least there is now an exposed region

of aluminum, and it is close to the edge of the preionizer,

which should help that work correctly.

(early afternoon, 28 August, 2006)

I have now built the gas ports. With any luck I should

be testing at room pressure within a few hours, when the

RTV has begun to harden. My apologies for the slight

motion blur in these photos; the light was less than

optimal. In fact, I had to shine a white LED up into the

end of the head to show the surface of the preionizer in

the second photo.

Notice that the preionizer extends well past the ends of

the electrodes. Also note the slanted bottom on the gas

port section, which unfortunately is not easily visible

in either photo. I built both of them this way, to

minimize the exposed areas on the sides, and also for

strength. As Bucky Fuller pointed out, a triangle

resists deformation a lot better than a square does.

(Yes, I know, the side-plate is a square, but that’s

because I had it handy; it is covering a triangular hole.)

(early that evening)

Initial tests give me lots of bright sparks from the

electrodes to the preionizer, and under some

circumstances there are lots of very small sparks, a

good sign. I suspect that the preionizer conducts a bit

too well, as I do not appear to be getting a

“regular” discharge, at least with helium at

1 atmosphere; but we’ll see how things go under

vacuum ...after the RTV sets, probably tomorrow morning

unless I just can’t stand it. (I certainly

should stand it — the stuff is still quite

soft now, and it won’t be even moderately hard for

at least another 12 hours.)

In the meanwhile, here are four views of part of the

channel, showing typical shots. The brighter sparks in

the laser are pink because the head is filled with

helium. If you want more detail, btw, change ".10c"

in the filename to ".22c". That gets you the crop I

made from the original image, unscaled. I think the

upper ones are in better overall focus than the lower

ones, but the right sides of the lower ones are okay.

One saving grace of this head design, btw, is the fact

that I can scrape the current preionizer off and put a

narrower one on, if I decide that it really is just too

conductive. It wouldn’t be fun, but I could do

it. Alternatively, I could just raise the roof a bit by

adding more spacers, which would put the preionizer

further from the electrodes. Again, annoying; but

certainly possible to do, which is good because I expect

to be doing it in a day or so.

(early AM, 29 August, 2006)

Based on what you can see in the photos above and on my

general sense of the behavior I observed it seemed

pointless to wait, so I have just removed the

“roof” and added an additional 1/8" of

spacing. It was certainly annoying, but I knew I might

have to do it, so I’d set up the head to make it

as easy as possible under the circumstances, and it

really didn’t take very long. It’s

done now, and when I wake up in the morning I should be

able to resume room-pressure testing. Later on

we’ll see about leaks...

(around 0900, 29 August, 2006)

Initial results at room pressure (arcs and sparks that

don’t actually appear to be going to the

preionizer) lead me to think that 1/8" may actually have

been a bit much, and I may eventually remove those

spacers and replace them with 1/16" ones; but I want to

do some testing at reduced pressure first, as that could

change the behavior significantly. Have to wait until the

RTV gets much stiffer, though, before I will feel good

about pulling vacuum on this head. Maybe tonight...

(early that afternoon)

I decided to apply Jarrod Kinsey’s excellent

methods: used a piece of polyethylene hose as a

stethoscope to find the leaks, and stopped them up with

a rather rubbery type of hot-glue. Took me perhaps 30

minutes to clean up just about everything (or so I

thought; see below for more about this), after which I

resumed testing. As far as I can tell, all I’m

getting is bright (and dim) sparks from the electrodes

to the preionizer, even with the spacing as wide as it

now is. I am somewhat surprised, but that’s what

I’m seeing. I want to try a variety of fill

pressures and mixtures, but I have not been able to do

much testing yet — the vacuum pump emits an oil fog

that I really don’t want to breathe; I have to

figure out a way to trap that stuff.

As long as I have this problem, let’s talk about it.

I have a lovely commercial roughing pump. Only one

problem: if it runs for more than a few seconds against

even a light load (for example, a nitrogen laser), the

exhaust becomes a nasty fog of oil droplets. In the best

of all possible worlds, there would be a neat way to

catch the fog and turn it back into liquid oil, which

would then drip back down into the pump: after all,

that’s where it belongs.

In the next-best world, there would be a way to catch

the fog and remove it from the exhaust of the pump, even

if there weren’t any good way to turn it back into

usable liquid oil.

In the mediocre (real) world, one runs the exhaust hose

to the great outdoors. Vacuum-pump oil of the ordinary

sort is a relatively innocuous material, and there are

bacteria in the soil that will eat it if they can get

their grubby mitts on it. For various reasons, however,

including the fact that vacuum pump oil is expensive, I

would prefer to let those bacteria eat other things.

There is a very pleasant way to remove dust and aerosols

from the air. It is called a Cottrell precipitator, and

it is a fine use of HV DC. You can operate a Cottrell

from an electrostatic source, and I believe that under

some circumstances you can even do it with AC.

Basically, you make an open-air capacitor; let the air

flow past the plates, and even modest amounts of corona

will charge the particles, which then stick to plates

charged one way or the other. (I have several commercial

electronic air filters that do this. They are quite good

at removing dust; I think the usual rating is 97% per

pass, and the size of the particles is not particularly

an issue, the way it is with HEPA or other mechanical

filtration methods. After room air passes through such a

device a few times, there is very little particulate

matter left in it. Unfortunately, a room-air cleaner is

not easily adapted to this service, so I’m going

to have to build something.)

I happen to have a nice old oil-burner transformer here,

courtesy the very kind fuel-oil place a door or two

down, which can serve as a source of high voltage. It is

time to do a spot of construction...

(late that evening)

I suspect that I have the “plates” (actually

pieces of brass screen) too far apart, as there is still

fog coming out of the pump. I will have to figure out a

way to reduce the spacing. I tried putting rectifiers

in, to make DC instead of AC, but it did not appear to

change the performance. Too bad — it would be

really nice if this thing worked. I want to get back to

messing with the laser.

(next morning, 30 August, 2006)

Well, hmmm. It may be simpler than I had thought.

This PDF file

shows a simple design, and comments that oil droplets

(at least in cigarette smoke) tend to be positively

charged, which tells me that I want DC and that I want

the negative pole in the middle. When I get a chance, I

will probably go get some PVC tube with a thin wall, and

see how this configuration works. That, however,

probably won’t be until tomorrow, as I am

scheduled all day today with other stuff. (Sigh.)

(NOTE, added 06 October, 2009: That PDF file is suspect. Milan

Karakas has found other information, and has verified it by

experiment. It is clear that insulating the conductors is

not a good idea, at least under ordinary circumstances.

See below for a rebuild of this device during October and

November of 2009.)

(31 August, 2006)

I took a piece of #8-32 threaded rod about 2 feet long

that was lying around, a couple small pieces of

fine-mesh brass screening, a piece of 3/4" PVC pipe from

the hardware store, some plain copper wire, and a

fitting to hold the pipe and sit on the outlet of the

pump, and constructed a device.

First, I made a hole in the middle of each piece of

screen and used hot-glue to attach them to the ends of

the pipe. Then I used a nut and a lockwasher on the

underside of the top screen, and an acorn nut and a

lockwasher (and a drop of hot-glue to prevent the

vibration of the pump from wiggling the acorn nut loose)

on the upper side, to position the piece of threaded rod

so that it hangs vertically in the center of the pipe. I

left a tab on the upper screen, to connect to the

negative terminal of my impromptu power supply. Then I

wound the copper wire around the outside of the pipe,

holding it in place with a tie-wrap at each end. That is

now connected to the positive terminal of the supply.

Here is an overview of the Cottrell on the pump, and then

a closer view of the negative terminal:

Net result: Much less aerosol, but if I run the pump

long enough, particularly if I am allowing some gas to

flow through the laser head, I do see some. I

will be looking into ways to improve this, as I need it

to be better than “some”. It is possible

that my HV rectifiers are not up to the task; I will be

testing them when I have time. I am bidding on some

others, which should have sufficient PIV rating to

serve. (I have pairs of 15 kV rectifiers now, and they

may not be stackable...)

(03 September, 2006)

I have rebuilt this precipitator, using about 4 feet

of 1/8" brass rod inside a pyrex tube down the center,

and with a much taller PVC tube on the outside. It

seems to work a bit better. Also, I am running it with

a commercial 20 kV supply, which probably helps.

(Note, added on 27 September, 2006: I did not get the

Cottrell unit to work the way I wanted, and I will

have to revisit it when there is time. I know that

Cottrell precipitators can be made to work quite well,

and I am very curious as to why mine doesn’t.)

(Note, added on 27 September, 2009: Milan Karakas has,

as mentioned above,provided some additional insight, and

I will be rebuilding the precipitator when I have time

and materials. It appears that an uninsulated wire down

the middle of a conductive tube works better than an

insulated wire down the middle of an insulating tube.

This is, in retrospect, not surprising, and we are

wondering why the PDF file referred to above specifies

otherwise. Be that as it may, I have started to build a

new device, which will be about 60 cm tall and will use

3-mil nichrome wire as its corona source.)

...But enough of this. Back to the laser.

I put a strong UV absorber between myself and the laser,

just in case (even though it has not yet shown any sign

of lasing), and examined the discharge. I am getting

bright sparks across the channel, which is both a good

sign and a bad sign. I’m happy that they go across

the channel and not just up to the preionizer; but

I’m unhappy that there are bright sparks rather

than a nice clean discharge. Have to think about what

might govern this and what to do about it.

(some hours later)

What I think is that I need to know just how much vacuum

I am achieving. Without that information, I am floundering

around in the dark.

I cleaned up one of my mechanical vacuum gauges so it

gives sensible readings, and put it on the system.

Couldn’t get any better than about 25" Hg. Went

over the head with Jarrod Kinsey’s stethoscope

method, and found two very small leaks. That bought me

perhaps another inch. It seemed possible that I was

getting some leakage through the wood, so I

fingerpainted RTV on almost all exposed wooden

surfaces. Here is a view of the underside of the

channel:

When I get back from rehearsal this evening, I will

check to see whether I get any better vacuum. If I

can’t get to at least 29" Hg (that’s a

little less than 23 Torr) I am not going to be able to

do a reasonable test, because there will be too much air

in the channel. (For reference, 1 Torr is the amount of

pressure it takes to raise a column of Hg by 1 mm, so

760 Torr, which is one standard atmosphere, amounts to

about 29.92" Hg. Needless to say, if you are in the

middle of a low-pressure zone, and the barometric

pressure is only 28.5", you are not going to pull 29.9"

of vacuum. Likewise if you live at a high altitude. This

kind of thing is why we prefer absolute pressure

measurements.)

In fact, it does:

This is just the beginning, but at least it is

a beginning. I was worried that there might be something

fundamentally wrong with either the design or the build.

Next I get to do some optimization, assuming that I

can get the precipitator to be fully functional.

(mid-morning, 01 September, 2006)

Here are two more photos. The first is the discharge as

it appears with perhaps 75 Torr fill pressure, a mixture

of helium and nitrogen (and some air). The second is the

output. These are both slightly out of focus, and

eventually I will try to take better ones.

The fact that the output looks like a donut is

somewhat unsettling, and I am going to have to

take a good hard look at it. I will also probably

have to put a mirror on one end of the laser, to

see what effect that has. I have acquired a piece

of 3/8" thick glass that will serve as a shelf

for the mirror mount to stand on, and I am

attaching it to the baseplate with RTV. I also

begin to think that it’s time to put a GP-15B

spark gap on this laser, and see what it does at

30 kV.

(03 September, 2006)

Here is a photo of the output at 20 kV driving the

fluorescence of a piece of bond paper. There is a mirror

at one end of the laser, and the gas pressure is vaguely

optimized. The mirror is quite difficult to adjust, and

may not actually be precisely “on” in this

photo, but it is fairly close. My apologies for the

polyethylene tube that cuts off the top right corner of

the output spot. It is the vacuum hose, and is difficult

to move because it goes to the gauge, which is quite

close to the target.

(Unfortunately, this is cropped straight out of the

original; there is no larger image.)

Small amusement for those who have dealt with high

voltages: because the baseplate is “hot”, I

had to hot-glue plastic bottlecaps onto the adjustment

knobs of the mirror mount, because otherwise I

couldn’t really touch them with the power on. (I

checked and found that even though the mirror mount is

sitting on a glass plate that keeps it insulated from

the base, I drew tiny sparks if I got my fingers within

about 3 mm of any of the knobs, so I decided to be safe

rather than sorry. It pays to be careful with these

devices!)

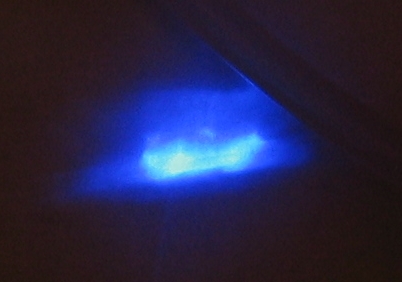

Here is the focused output of this laser, pumping

my homebrew cuvette

to superfluorescence. The dye in the photo on the left

is Rhodamine 6G of rather dubious purity (certainly not

laser grade), and in the photo on the right is

7-Diethylamino-4-Methyl-Coumarin of somewhat better

quality; both are dissolved in 95% ethanol:

The output is the greenish double stripe at the upper

left, on the piece of paper. The first focusing lens is

not readily visible in these photos, but you may be able

to see the second lens, which is cylindrical. In the

photo on the left, the laser is not well optimized. It

had no trouble lasing the dye, however, even with no

external mirrors, and with the walls of the cuvette

deliberately misaligned from the front window so that

they cannot function as mirrors. In the photo on the

right, I have improved the focusing and adjusted the

gas pressure slightly, and the laser is using a larger

spark gap that is connected with considerably broader

pieces of brass shim stock, so it should be switching

slightly faster and possibly producing slightly higher

output power.

(05 September, 2006)

In preparation for running this laser at higher voltages,

I have painted the underside of the head and parts of the

brass shims with HV insulating varnish. When that dries

I will reassemble the laser and try it on the bench,

where I have a larger HV power supply.

(later, that same day)

Here is the laser on the bench. Directly above and behind

it is the electrostatic voltmeter. You can see part of

the trigger unit in the foreground, and

a commercial TEA nitrogen laser in the right rear.

I have now run the new laser as high as about 28 kV, and

it continues to perform quite well.

Here is something you just don’t get to see every

day — I accidentally got the concentration of dye

in this solution (it’s Rhodamine 6G) a little bit

low, and as you can see in the photo, I am lasing it by

pumping it longitudinally:

If you want to do this deliberately, you will probably

find that it is easier with Fluorescein, which does

not absorb particularly well at 337 nm. (I tested, and

it worked on my first try.) As a start, you may want to

adjust the concentration until essentially all of the

pump light is absorbed in the first 1/4 to 1/2 of the

cuvette; see how things go from there.

It is also possible to lase some kinds of fluorescent

plastic sheet this way, and I once saw some video

footage; but I rarely observe longitudinal pumping in my

own setups, and have not yet succeeded in thresholding

any of the samples of fluorescent plastic sheet I

have. Perhaps as I get this laser better optimized I

will try again.

(05 September, 2006)

Pulsing the laser once per second, focusing the beam

into a Scientech head, and running the output through a

x100 instrumentation amplifier, I get a reading that

corresponds to about 0.67 milliwatts. That’s

roughly 670 microjoules per pulse. I am hoping that I

will eventually get considerably more out of this laser,

but it will take additional optimization, possibly

including finding and fixing more leaks.

Here are four representative output pulses. These were

taken at 25-27 kV (the last one is around 27, but I am

not entirely sure about the others). The last one also

shows what happens when I tweak the gas pressure. It is

a little better than most, but still fairly

representative. (My apologies about the blur. The

camera seems to have some doubts about how to focus.)

These are at 2 nsec per division on the screen. The

sensor is a Motorola MRD500 photodiode, with bias

provided by 6x 9V batteries in series, for ~54 VDC. The

signal from the diode goes down a piece of 50-ohm

coaxial cable that is about 8" long, directly into the

input of a 7A19 vertical amplifier (600 MHz bandwidth)

in a Tektronix 7104 mainframe (1 GHz bandwidth). The

risetime of this setup should be 1 nsec or a bit less,

and is most likely limited by the photodiode.

Please notice that the FWHM pulsewidth here is 9-10 nsec

in the first two photos; 6 or 7 in the third photo (it

kinda hangs at the 50% mark for a while before finally

dropping); and 4 nsec in the last photo, largely because

of the tall first peak. The peak power of the pulse in

the last photo is much higher than the peak power in any

of the others, but I suspect that the pulse energy is

largest in the second photo. The fill gas for all of

these, btw, was just nitrogen (except for any air that

got in through leaks). I have not yet tried examining

the pulse with nitrogen and helium together.

Here, just because it happened, is the result of putting

too much energy into the photodiode. This was at 10 nsec

per box...

I knew it couldn’t really be an accurate record of

the laser’s output, but when I blocked the light I

didn’t get a trace, so it was clearly a real

signal, and it was coming from the photodiode. Took me a

little while to figure out what was going on. I then put

a piece of 1/4" window glass and some fluorescent

plastic in front of the laser, which absorbed enough of

the beam that the diode could handle what remained. I

found, btw, that I had to choose carefully. Even a 1-mm

thickness of the plastic that appears to be doped with

Rhodamine B absorbs essentially all of the nitrogen

laser’s output. (The plastic did not lase, partly

because the output of the nitrogen laser was not focused.

I will probably be trying again at some point.)

(evening of 06 September, 2006)

After dinner, I optimized the pressure by watching the

scope as I fired the laser. With the current mix of

nitrogen and helium, the traces were tallest and

probably widest at 25.2". (I should note that I do not

have gas flow meters, so I don’t really know

what the precise mix is.) I then put the power meter

head in front of the laser, and measured the energy.

This turns out to be, very roughly, 1.2 millijoule per

pulse. Given a pulsewidth of about 8 nsec FWHM, which

may actually be a bit on the long side — see

photos, below — we are looking at peak power on the

order of 150 kW. (The 10-10 pulsewidth is considerably

longer, and the average power is only perhaps 100 kW.)

Unfortunately, I did not get a picture of the optimized

trace; but I have other traces here, taken at various

pressures that I have labelled on the small images.

Notice that with both gas mixtures shown here, I am

getting best operation around 26.5 to 27.5" of vacuum;

I don’t know how to reconcile that with the 25.2"

that I was getting earlier, though that mixture may have

had a significantly different ratio of helium to

nitrogen.

[Note: if you click any of these, you’ll get a

1080x870 px enlargement. That larger image is a

direct crop from my original, and is the largest size

I have. The traces, btw, should be easier to see on

the enlargements; they did not show up well, so I

tweaked the green levels to make them more apparent.))

There is considerable variation in the pulse shape

(and the height) from shot to shot, as you can tell

by the fact that the 24" trace with nitrogen and

helium is slightly higher than the 24.5" trace.

Notice that there is clear evidence of a double peak in

some of the traces, particularly around 27 to 26".

You can compare those with these two pulses, showing

the two gas mixes at the same pressure:

Another thing that I am beginning to observe (but have

not yet had a chance to photograph) is that if I pulse

the laser and then pulse it again a little less than a

second later, the peak at the beginning of the second

pulse is generally a lot stronger. In fact, if I start

with a good first pulse at 27 or 27.5", the peak of the

second pulse is usually off the top of the screen. It is

very likely that this indicates inadequate preionization,

and I may decide to grit my teeth, rip the roof off the

head, and bring it back down to its original height. I

dread the process of finding and fixing the leaks, but I

really want to know...

(08 September, 2006)

I took off the lid and tried to remove the added spacers.

This failed, so I built another lid. The main spacers are

3/16" thick, and the preionizer is on a piece of spruce

that is 1/8" thick, so it is back to its original location,

1/16" above the height of the electrodes.

The preionizer is warped, but it seems to be of uniform

width, so the total gap is about the same all along even

if one side is wider than the other. I am seeing some

bright sparks, and I was prepared to build yet another

roof for this head if necessary, but the device is

definitely a laser — I have already used it to pump

and tune some R6G. When I get a chance, I will make some

measurements on it, but first I want to find and fix any

leaks I can. Even moderate quantities of air are bad for

performance, and I can tell that I have to let a little

more gas into the head now, before I see lasing. I’d

like to get it at least as vacuum-tight as it was earlier.

(some time later)

I decided, after measuring less than 900 μjoules

per pulse, that this roof was less than satisfactory.

After some thought I decide to cover the entire

underside of the next roof with SiC, which meant that

I’d be unable to see the discharge in any case,

so I made a new roof out of wood. Here’s a view

of the “carborundum carpet” on the

“ceiling”:

Reasonably nice smooth coating of carborundum, 7/8"

wide. Sorry the photo is slightly blurry.

(afternoon of 09 September, 2006)

I have found three smallish (but clearly significant)

leaks, and applied RTV to them. Tomorrow morning when I

get up (or around 2 am, if I’m still awake), when

the RTV on the third one is reasonably firm, I will

check again to see how well the head holds vacuum. So

far, I am not seeing very much change as I find and

fill these things; but they have all been right near

the vacuum port, so that isn’t too surprising.

(afternoon of 10 September, 2006)

It was essentially impossible to fix the leaks, partly

because I had not clamped the roof onto the head when

I attached it, and the weights I used were not heavy

enough; the new roof is slightly warped, and it sits

a wee bit up in the air ...until I pump on it. The

motion was reopening the leaks, so I finally gave up,

removed and reglued the vacuum port, and started the

de-leaking process again this morning.

That went well, so I fingerpainted RTV over almost all

of the exposed wood on the top. I just measured about

230 kW output, and that’s with a small amount of

the beam obscured by some RTV on the inside of one of

the windows. (See photos, below.)

(NOTE, added much later: the paintable RTV that I used

for this seems to be the wrong type. If you must seal

anything with silicone caulking, the kind that smells

like vinegar as it cures is probably a better bet.)

There is a distinct problem about this: the RTV should

not actually be in the beam path. The beam is shaped

like one or two curved lines (depending on pressure and

voltage), and I am convinced that this is because the

faces of the electrodes still have the anodizing on

them, so the discharge actually goes from upper edge to

upper edge and from lower edge to lower edge. I have

acquired a small diamond grindstone at the hardware

store, and the next time I take the roof off this laser,

I will attempt to get the anodizing off the electrode

faces with it. That may not help, btw. If it increases

the volume of the discharge too much, the laser may not

be able to pump the gas as well, which would actually

reduce the output. Mind you, I doubt that this will turn

out to be the case, but it is definitely a possibility.

Here is a look at the window, so you can see the RTV,

and then a look at the output. Unfortunately, I had

the camera a bit far away from the target, so the

512x384 enlargement is as big as I have right now.

You can see the mountain shape all too clearly on the

target. As I say, if I take off the roof again I will

remove the excess RTV, but I hope it won’t

actually be necessary.

If I have measured the power correctly, it should be

possible to create a spark on a metal surface by

focusing the beam. I will be trying that this evening,

and will attempt to photograph it if I can do it.

...And, in fact, it is possible. Here’s

the target, the target with a spark, and then tight

crops, one from the second photo and another (even more

out of focus, alas) that I took with the room lights out.

I have removed the RTV from the inside of the window,

and attempted to remove the anodizing from the edges of

the electrodes, with indifferent success. The head is

now reassembled and the RTV is setting, so I won’t

be able to do any further testing for nearly 24 hours.

Such is life; when there is any news worth reporting

(for example, output of significantly more than 250 kW,

or if I find that I can pump a dye laser with the

unfocused beam), I’ll report it, probably with

photos.

(evening of 11 September, 2006)

The de-leaking process continues. I have eliminated

several fairly gross holes, the latest one only a short

time ago, so the RTV on it is still wet. I should be

able to resume leak-testing some time tomorrow.

In the meanwhile, I should note that I will be

constructing a new head for this laser. It will have a

channel about 25 mm (roughly an inch) across, so I can

see whether that works better than the relatively tight

spacing (about 16 mm, roughly 5/8") of the current head.

The initial preionization method will be essentially

the same — a “carborundum carpet” on

the ceiling, this time just over an inch across, and

again 1/4" up.

I bought two painted rulers today, in the hope that they

are not anodized, as paint is going to be a lot easier

to remove from the working edges. They are now cut down

to 35" length, just a bit longer than the ones in the

first head. This means I have to position the mounting

holes slightly differently, by 1/4", but that’s

easy enough.

(27 September, 2006)

I built the new head with 1" channel spacing, which was

probably a bit large for this laser. Nonetheless, it

put out almost 240 kW. At that point I decided to return

to the charge-transfer laser on the third page of this

series (005b1.html), to find out whether I can coax better

performance from it. I am also working up the “How

to Build This Device” page. (See links, below.)

(27 September, 2009)

I need a nitrogen laser for one of my projects. Because

I have disassembled the one I’m currently working

on so I can do a major rebuild of its head, which is

complicated and will take considerable time and effort,

I decided to reconstruct this one. In the process of

doing so I have been having a very difficult time

“de-leaking” the head, which prompts both

the addendum about wood porosity above, and this second

addendum.

Note: in addition to the porosity issue, it appears that

the plastic fittings that I used in the initial version

are not really suitable for use in vacuum systems. They

perform nicely with pressure in them, but under vacuum

they allow too much air into the head unless, perhaps,

you operate with a large amount of helium in the gas

mixture. For this rebuild I have substituted ordinary

brass compression fittings, but with one difference:

instead of the brass compression rings that came with

the fittings or delrin rings (available at the hardware

store), I am using pairs of small o-rings. This allows

me to tighten the nuts by hand if I am careful.

I’m not sure whether Delrin rings would permit you

to tighten the nuts by hand, but they may be viable

[with a wrench] if you can’t find appropriate

o-rings.

The rings I’m using are 1/16" thickness, and have

inside diameter just a bit smaller than the

polypropylene or polyethylene tubing that I’m

using for gas and vacuum, so I have to stretch them a

little to get them on. I use them in pairs because a

single ring does not provide an adequate seal; the nut

goes all the way onto the fitting without compressing

the ring. That is, the second ring is just a spacer, and

you could substitute something else for it if you

wanted; but it seems simpler just to buy them in pairs.

(02 October, 2009)

Meanwhile, I have found about as many leaks as I can by

just dipping the ends of the head into water, and I have

built a trough that should allow me to dip the entire

head. When all of the caulk sets, I will give it a try.

(05 October, 2009, evening)

Having completed the trough I dipped the head into it,

and discovered that in addition to a very small leak at

one end and a somewhat larger leak at the other end,

there were various leaks along the upper sidewall. I

originally attempted to seal this sidewall with RTV, but

as I mention above I used a type that can be painted.

This turns out to be a mistake, and I cannot recommend

it. In fact, I strongly suspect that RTV is not a truly

optimal sealant for large areas of wood, and may not be

a particularly good sealant for wood in general.

Last night I sealed two more wooden yardsticks with

thinned epoxy, with the thought that I would use them to

replace the sidewalls on the existing head. As of this

afternoon, however, I have decided to put that effort on

hold and make a new head first, using plastic sidewalls

instead of wooden ones. (See

the follow-on page

for details.)

Citations for some interesting papers about nitrogen and other lasers...

To the first page in this set, a general discussion

of the issues involved in designing and building a

high-performance nitrogen laser

To a page about my initial effort to produce a

high-performance nitrogen laser

To a page about my continuation of that effort,

which resulted in a laser that puts out about 100 kW and

can operate without a vacuum pump

To a “How-To” page about that laser

To an interim page about my effort to scale up a published design

in order to enhance its performance

To the next page about this laser

To a page about my current (late 2006) effort to build

a less-expensive laser with even better performance

To the Joss Research Institute Website

To my current research homepage

My email address is a@b.com, where a is my first name

(jon, only 3 letters, no “h”), and b is joss.

My phone number is +1 240 604 4495.

Last modified: Wed May 10 14:54:38 EDT 2017

Yet Another ReDesign (YARD)

Sidebar: Preionization Techniques

The Build Continues

Sidebar: Capacitor Improvement 101

Interlude: Vacuum

Possible Method #1: The Cottrell Precipitator

Power and Energy Measurements

First set, nitrogen and helium:

Second set, just nitrogen:

Rework, September-November, 2009:

References

the Joss Research Institute

Contact Information: