First, here’s a photo of the parts I bought when I started the project:

The total cost of what you see here was just under $17; but you also have to add the cost of glue and a few nuts and bolts that aren&squo;t shown here, so let’s call it $20. That’s unrealistically high, though, because there is more here than you need for one mount.

This mount is very easy to construct; it took us (I had help and advice from our loyal Range Safety Officer, LisaJulie Peoples) only 2 or 3 hours to assemble the prototype, even though we had to figure out what we were doing as we did it.

Please note that this first version is what I like to refer to as a “PoP machine”; that is, it is intended to provide Proof of Principle, and is not as robust as a final version. For example, this one is glued together with CA (Cyanoacrylate) glue; the real thing, further down the page, is glued with epoxy, which is much stronger and less brittle. It also doesn’t deposit white powder all over everything in its vicinity as it cures. (Ahem. Grump.)

Not Quite Step by Step:

I was too excited while building the prototype to take photos of the early steps, but I have annotated the first one to make this a bit easier to follow.

Draw or scribe lines on the back of the rider. They should be in line with the holes that define the X and Y rotation axes. (These lines are indicated in purple in the photo, immediately below.) The pivot goes where the lines cross; glue on either a steel ball (which can sit on a washer for added gluing strength and ease of positioning) or an acorn nut (which is easier to find, and will work adequately well). There is a detail photo, further down, showing the way I made the pivot on the prototype.

[I did not, btw, perform any machining on these pieces; all modifications were made by gluing things on. The one bit of machining shows up later, on the mirror holder.]

Glue nuts on the outermost holes of the rider. The adjustment screws will pass through these. (Later, we will add a secondary nut, to take out most of the backlash; for now, though, a single nut should do.) If you have trouble with the countersinking, just glue a washer on first. Then glue the nut over the hole in the middle of the washer. Remember to keep things as well centered as possible.

[NOTE: I describe a considerably more precise version of this mount later; you probably want to read through the entire description before you start acquiring parts or doing any construction.]

Position the rider on the stand, with a washer under the steel ball or acorn nut. (Your choice about exact positioning, but I will suggest that it is probably easiest and most effective to match the upper/inner edges.) Glue the washer into place, being careful not to get the acorn nut or steel ball stuck to it.

It’s a good idea to round the ends of the adjustment screws a bit, so that they move smoothly on the surface of the stand. You may also want to file or sand the surface smooth. For the proto, however, I didn’t bother. (Please note that we will get to a considerably better way to deal with this issue in a later version.)

I put smaller washers under the ends of the adjustment screws, to keep them from wandering about; but if you can arrange short narrow channels for them to “walk” along, that would be significantly less wobbly and more precise. (I actually did that in a later version of the mount, which is described further down the page.)

I glued the gusset and stand to the baseplate together; then I attached the rider to the stand.

You need at least one spring to hold the rider onto the stand, so that the adjustment screws will have something to push against. If you can attach a short strong spring in the inside corner, that will do. I didn’t have a spring of the right type, so instead I took a pair of o-rings from the assortment, and used one on each axis. They were just a bit long, so I put a twist into each one to tighten it. (Again, see the photos.)

Here are some views of the completed frame, before I added the mirror holder:

Here are two details, showing the washers I am using to keep the adjustment screws from wandering, and the pivot point:

A steel ball, if you can find one of a reasonable size, is a better pivot than an acorn nut. I found steel balls at my favorite local hardware store (an Ace Hardware called Zimmerman’s), but I built the prototype with an acorn nut because those are much more commonly available. We will get to steel balls when we do the improved versions of the mount, further down the page.

Here is a detail showing the second nut on one of the adjustment screws. I tightened this nut only until it became very slightly difficult to rotate the screw; then I glued it into place. This essentially eliminates backlash and wobble, and makes the mount considerably more precise. It also reduces the travel range slightly, but if I can find a longer screw at some point I can substitute it for the one that is currently in place.

[Note, added on 15 September, 2007: if you use sufficiently strong springs, and if the round ends of the adjustment screws are held in place, as they are in the third version of the mount, you probably don’t need anti-backlash nuts. They are, however, easy enough to make, and they do stabilize things, so I would suggest using them anyway.]

I made the mirror cell from large washers and o-rings. You can see most of the details from the photos. The one bit of machining I did was to drill holes in the mirror cell pieces for the bolts that hold it together. I used a drillpress for this, but you could do it with an ordinary drill if your hand is reasonably steady. (If you want to get fancy, you could drill both ends with the tap-drill size, then redrill one end with the body drill, and tap the other end. I just glued nuts onto one end.)

Here is what the mount looks like with the mirror holder in place:

The two washers that are visible in the photo on the left are basically gussets; the joints between the mirror holder and the frame consist of tiny dots of CA, and just aren’t strong enough, so I have reinforced them. (I would probably reinforce them even if they were epoxy, but you should probably take a look at the later versions of the mount for a slightly different and somewhat easier approach to this entire issue.)

Because I wanted to have a broad surface for the washers, I installed the mirror cell with the mirror hanging out the front. This is perhaps not the best orientation; left to its own devices, the mount falls on its face. While it is true that you will ordinarily be holding it firmly in place on an optical table of some sort, it is still a good idea to have it be stable on its own; you can use a wider baseplate, or use narrow gussets and orient the cell with the mirror behind the rider, rather than in front of it. (In fact, I reworked the prototype this way; see photos, below.)

This mirror holder is intended for 15mm optics. I also built one for 12.5mm or ½" optics, but did not put it on:

I am thinking about ways to make it easy to swap cells or to build a cell that holds multiple sizes of mirror, and if I get somewhere with either of those I will add a description.

Here are two photos of the mount on the bench, with a mirror installed in it. As you can see, I have broadened the baseplate so the mount doesn’t tip over.

After I did that I found some very nice mending plates at Zimmerman’s, and I may just swap out the base. Here are the mending plates, the single-edge blades I hope to use as replacements for the washers that the adjustment screws ride in (I was lucky enough to find very small ones, but if you can’t find little ones like these, you could probably use injector razor blades), and steel balls in several sizes:

Version 2:

Let’s Try For a Bit More Precision

Having noticed that the ends of the adjustment screws were wobbling around in the washers that I used in the prototype, I decided that I wanted to have them ride in short channels, which would constrain them along the axes. (This is common in commercial mounts.) In order for this to work, the screws must terminate in smooth rounded ends. Rather than try to round them off, which is difficult even with access to machine tools, I decided to attach small steel balls to them. That’s not entirely trivial, so I thought for a while about how to accomplish it.

My first decent idea was to take a drill that is just big enough to make a body hole for the bolt, drill into something firm, drop the ball (which, obviously, can’t be any larger than the drill size) down the hole so that it lodges in the conical end shape left by the drill (which automatically centers it), put a dab of glue on the end of the bolt, and push the bolt in until it touches the ball. When the glue has set, you can remove the bolt.

This method requires a hole that is just barely big enough. The M3 bolts I acquired (initially intending to use them in the translation stage that I describe below), are about 2.91 mm in diameter; The closest drills I had on hand were ~2.75 and ~3.13. (I measured them with cheap electronic calipers, so don’t trust the last digit.) I thought about that for a while, and decided that if I used a slightly small drill, and drilled the hole in fairly soft material, I could probably just screw the bolt into the hole until it reached the ball. This should provide better centering than a hole that is wide enough for the bolt to wiggle inside it.

The first material I tried was end-grain balsa wood. That’s probably a little bit too soft, so I went for end-grain basswood on my second attempt. I am now beginning to think that it is probably necessary to clean up the end of the bolt a bit before attempting to glue the ball to it, and I am not sure that even basswood is hard enough.

(27 August, 2007)

Yesterday I drilled into a harder piece of wood, and found that it seemed to work slightly better. I also measured a 4-40 screw; it was about 2.80 mm diameter, so the drill that measured 2.75 mm is probably a nice fit for it. Today, however, I went to Zimmerman’s and discovered that a #32 drill is just the right size for an M3/0.50 bolt: my calipers give it as 2.93 mm, and if I drill into pine (I used a scrap that had been cut from a 2x4) the screws just slip into the holes with a little effort. This ends up working extremely well, though occasionally one of the balls ends up being somewhat off-center, so you need to check them before you use them.

Here’s a photo of an M3 with a ball on it, sitting on the piece of scrap that I drilled the holes in:

I then went back to Zimmerman’s and found special wire-gauge drills. The #34 drill turns out to be just about right for a #4-40 screw, and I had no trouble putting small steel balls on the ends of the adjusting screws for the mount. (More about this, however, later.)

As long as we’re going for precision, I removed the acorn nut from the stand and put a washer in its place. This time, we will use a steel ball. I also scribed lines on the stand, to indicate positions for the V-channels that the little balls on the ends of the adjustment screws will ride in, and also for the washer that the pivot ball rides in. Here is a photo of another L, showing this:

To make the V-channels, I started with one of the tiny razorblades I show above. I snapped it in half, because the travel distance involved is so tiny that I don’t need anything like the full length. (Safety note! Use Vise-Grips® or other locking pliers, wear safety glasses or goggles, and snap away from yourself! Also, be careful of your fingers around sharp edges.) The blades are quite brittle, so it should be relatively easy to snap them. If you are having trouble, re-examine your setup.

The blades need to be tilted to create channels, so I glued a 1/16" ball under each of the pieces, and used CA to glue them down to the stand. (Remember to wipe the oil off them before you try any gluing. Again, be careful.) Here they are, before I glued them down:

As you can see from the next photo, there wasn’t enough room for a steel ball under the opposite side of the channel, so instead I used short pieces of wire-wrap post, which I happened to have lying around. This makes the channels asymmetric, but I doubt that it will be an issue.

I found that I had to snap the back edges off the blades, because otherwise they were unbalanced and fell off when I tried to position them. In fact, gluing the bits for this was very delicate work, and I had to reposition things once or twice.

As long as I had things apart, I flipped the traveller over so that the mirror cell would be over the [new] base, and the mount would not try to tip over. I also substituted M3/0.50 screws, which have finer thread pitch, for the #4-40s I was using. The 3/32" balls work very well with M3 screws, but if you go with #4-40 screws you will also want to go with 1/16" steel balls, which will fit through #4-40 nuts. That, or be sure to put the nuts on before you do your gluing. Ahem. (Yes, my mileage varied. The 4-40 socket-head capscrews look very nice with the 3/32" balls on them, but when I tried to put them back onto the mount, they, uhhh... hmmm. Yes. Well. M3 it is, then. We will, however, return to this issue later, and make good use of it.)

The positioning of the pivot appears to be even more tweaky and crucial than I had thought, and I’m not sure I have it right even now. It turns out that the channels fix the position of the ball, and if the washers for the pivot are not precisely where they need to be, one of the adjustment screws (or both) won’t sit in the center of the channel, or will walk out of the channel as you adjust the mount. This also happens if the channels are not aligned well, which is basically saying the same thing. I may have to figure out a more advanced way to build this version. (Makes me want a rather precise 3-axis positioner, but that’s a large project in and of itself.)

I am lightening the mirror cell, which is just too heavy for this somewhat more delicate design. I have ditched both of the larger/thicker washers, and I’ve been looking around for other ways to hold the o-rings in position. One thing that suggests itself is part of a faucet aerator, which you can see in the photos below. Another is the neoprene washer from a garden hose. Both are very slightly large, but I think they’ll do.

Here are two views of the nearly-completed mount. (The back half of the mirror cell is not attached.)

It occurs to me (time for a small epiphany, I guess) that the only way to prevent at least one of the adjustment screws from walking out of its track as the other screw is moved through a wide range is to put the pivot point (which in this design is at the center of the pivot ball) in the same plane as the V-channels. (You can accomplish this by drilling a hole, just almost large enough for the ball to go through, in the stand. Glue the ball in place. Let it ride in a washer that, if necessary, is held a short distance away from the rider on a stalk.)

In the meanwhile this mount is quite usable over a range

of perhaps a degree or three in both axes, and I think

it’s a very decent start. On the other hand, it’s

annoyingly tweaky to build because everything has to be

lined up really carefully and accurately, so...

(29 August, 2007)

Version 2 of the mount is certainly viable in a general

sense, but I want something simpler that works at least

as well. It occurred to me that instead of trying to get

the ball-ends of the screws to run in channels, it might

be possible to maintain the position of the ball end,

and take up the slack elsewhere.

The issue here is that if I position the ball end of the

screw firmly, the angle that the screw makes with the

rider must change as the angle of the rider changes. If

the pivot point is not coplanar with the ball ends of

the screws, the angle changes in both axes. I originally

thought about bearings and/or slides, but the

aforementioned Range Safety Officer suggested neoprene,

in the form of o-rings, grommets, or faucet washers, for

the compliant couplings. At first the neoprene idea

seemed like it might be too loose, but after some

thought I decided to give it a try. I found, somewhat to

my surprise, that faucet washers are probably too stiff,

and I have switched to o-rings. O-rings appear to be

just about right for this, and the revised design is

noticeably simpler than the previous version. (There

will, however, be further changes, so please keep

reading.)

I am working up a diagram to illustrate the angle issue,

but it isn’t finished yet. When it is, I will

post it here. In the meanwhile, here are some photos of

the mount as it goes together. First, a detail of the

pivot point and a detail of one of the adjustment screws.

As you can see, I have drilled a hole in the stand. I

could have put the holders for the adjustment screw ends

on blocks as an alternative, but this was easier. (The

holders, btw, are just #4-40 nuts. Inasmuch as it was

clear that the little steel balls wouldn’t go

through them, they seemed like the obvious thing to use

here, and they work quite well.) If you build one of

these, it’s your choice. I will note, btw, that

the column you see on top of the pivot ball in these

photos is a little bit too long for the adjustment

screws I’m using now; I will be removing the nut

that is currently acting as a spacer. (In the photo on

the left, and in the inverted photo below, also on the

left, this nut appears at the base of the column.)

In the photo on the right you can see the o-ring, just

below and to the left of the anti-backlash nut assembly.

(There is a washer between it and the nut; I used CA to

attach the o-ring to the rider and the washer, and then

epoxy to attach the first nut to the washer and the

second nut to the first one.) Here are two overviews of

the mechanism:

Here is one of the screws just about fully extended, and

just about fully retracted:

The dark liquid on the screw in the photo on the left is

a wonderful lubricant called Dri-Slide®, which is

made by Lilly Industries. It contains molybdenum

disulfide, and will even work in vacuum after the

carrier evaporates, which takes a while.

Here is the basic mechanism on the base; I have removed

the hex nut (and the washer) from the column extending

“up” (in this photo, to the right) from the

pivot point to the rider:

I would not have bothered to remove those extensions

if my M3 adjustment screws had been 25 mm long; but

the longest I could find at the store was 20 mm.

It’s not quite over yet, though — I still

have to decide how I will make the mirror cell. I may

bite the bullet and design a cell that can be swapped

out, so I can change mirror sizes easily.

(30 August, 2007)

After considerable fussing in the plumbing department

at the hardware store, and then searching through my

odds and ends here, I have come up with what I think

is a viable mirror cell, at least for 15 mm mirrors.

(It may be possible to adapt it to 12.5 mm mirrors,

depending on the availability of appropriate washers

and o-rings.) Photos:

This is the body of a sink aerator, with a washer

dropped into the bottom as a stop; on top of the washer

are two o-rings (obviously, if I just put the smaller

one in by itself, it would not remain centered). The

mirror is centered by a neoprene washer, and is held

in by an adapter onto which I epoxied another washer

(again, as a stop), and into which I dropped another

o-ring. (Adapter, washer, and o-ring are on the left

in the first picture; mirror in the middle; aerator

body, washer, o-ring, and neoprene washer on the right.)

(Note, added on 31 August, 2007)

I went back to Zimmerman’s and found that they

sell aerators with the adapters already in them, which

makes this a whole lot simpler. Here are two types:

These do require a bit of care when you go to attach

them to the mount, as they are tapered, but it

isn’t particularly difficult.

(end of note)

The mount is now complete; let’s put the mirror in,

and see how well it works...

...The first thing I noticed, after I got it onto the

bench, was that the adjustment range is huge; it seems

to be about +/- 5° in each axis, though I

haven’t actually measured it yet. (I put a HeNe

with a white card on the front a little less than a foot

and a half away from the mount, so I could see the

return, and at the end of the adjustment range the

return was off on the wall someplace, a surprising

angular distance from the laser.)

Coarse adjustment was easy, but when it came to fine

tweaking I found myself wishing I had socket-head

cap screws. Such is life: I used what I could find.

(You can always go to

MSC Industrial Supply

if you decide you want stuff that is fancier than

whatever your local hardware store has in stock.)

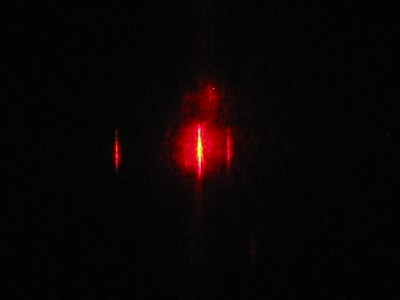

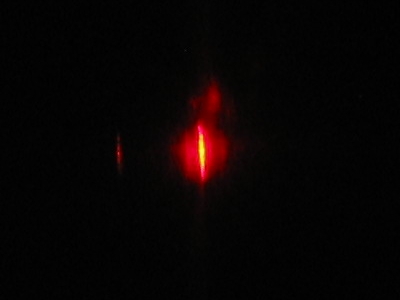

Here are two photos of the front of the laser, with

the return beam from the mirror going straight back

into it:

The laser did a lot of mode-hopping at first, even

though the mirror is quite blue and does not reflect

much in the red part of the spectrum. You can see some

of the appearance of mode-hopping in the photos above,

though of course it is a dynamic process, and I should

probably take a video of it. What really caught me by

surprise was something I was not able to capture

directly with the camera: the laser also changed color

for short periods (!).

If you were not already aware of this, HeNe can put out

several visible lines, including green (543.5nm), yellow

(594nm), and orange (612nm), in addition to the usual

red at 633 nm, a slightly longer red, and some lines in

the IR, of which I think 1523 nm is the most common. In

fact, the first gas laser was a HeNe, and it ran on one

of the strong IR lines, not the red we are now so

familiar with. (That came along a month or two later.)

In connection with this, btw, I seem to recall that 6 or

7 of the lines share a common upper state. Because the

cross-section for stimulated emission decreases as the

wavelength gets shorter, it is easiest to get lasing on

the longest line of the set, which happens to be an IR

line. In fact, if you have a very high-power HeNe, with

a long tube, you have to take steps to get much power in

the visible, as the IR line tends to operate even with

red mirrors, and it steals power from the red line.

The green line, being the shortest, is the most

difficult to lase, and 543.5 nm “GreNe”

[that may be a trademark] lasers generally don’t

put out much power — I think half a milliwatt is

fairly common. They also tend to be rather expensive.

After lots of fruitless attempts to show the color

change by pointing the camera at the laser, I put the

spectroscope (bottom of this page) behind the mirror,

and managed to get some evidence.

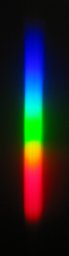

Here are 5 photos. The first shows just the regular HeNe

red at ~633 nm; if you look at the second carefully, you

may be able to make out just the ghost of a second line,

a little to the left of the main one. In the third image

there is a line to the right of the main one

(possibly 640.2 nm), and at least two ghosts to the

left. The fourth image clearly shows the orange line to

the left, and the line to the right; in the fifth, the

line to the right of 633 has gone away, but there is

still some orange coming out of the laser. (The camera

does not capture the colors well; the line that is well

separated from the main line on the left is distinctly

orange or yellow-orange to the eye, and the main beam,

which is overexposed here and looks bright yellow or

almost white, is the usual HeNe red color.)

(These are full-size crops from the original images,

so unfortunately I don’t have any that are larger.)

The laser did less and less mode-hopping as it warmed up

and stabilized, and there were fewer and fewer moments

when it changed color, though I found that I could

sometimes get a certain amount of color change for a

brief period by tweaking the mirror a little.

These photos are not really what this is about; but this

is the first time I’ve been entirely sure that I

was seeing a plain-vanilla red HeNe putting out other

colors, and I thought that was pretty interesting.

In any case, it is abundantly clear that although the

mount is a bit soft, in the sense that it bends a little

if you push with the screwdriver when you are adjusting

it, it is a pretty decent mount. It is reasonably easy

to adjust and set, and it holds a setting fairly well.

If you don’t need the very wide adjustment

range that this specific version provides, you could

easily just widen the holes in the L bracket a bit,

epoxy thin washers over them, and put the adjustment

screws through those. Remember to retract the screws

most of the way when you attach the receivers that the

balls ride in, to minimize the maximum angular

offset. That should give you a stiffer mount. In fact,

see below — I decided to try doing this.

Here is the beginning of what I am currently calling Rev

3A. It will have less range, but should be more precise,

as I am using larger brackets. It should also be slightly

stiffer; instead of o-rings, I am using the very slight

springiness of brass (bronze?) washers. Here are some of

the pieces:

The first step is to attach the large washers to the

traveller; then the small washers go on top of those.

In the photo on the left, I have some machine screws as

positioning aids, and the epoxy is on the large washers,

waiting for the small ones to be placed. Once all of

that has set, the anti-backlash nuts go on the small

washers (which, btw, are #6), and the anti-backlash

nuts go on the small washers. In the second photo, I

have the first half of each anti-backlash nut in place.

Notice the fact that I have (carefully!) sawed off

the lower edges of the washers, so that the bottom

of the horizontal-axis one won’t hit the base.

I haven’t decided which one will end up being

horizontal, so I sawed them both.

(03 September, 2007)

The above version of the mount, when I tested it, worked

fairly well; but I did notice that it was still a bit

more rubbery than I would have liked. When I tried to

adjust it, the pressure of the screwdriver made a

noticeable difference in the setting, which made it hard

to get precise control. I did succeed, but it was by

guessing where the aiming point would be when I let go.

That just isn’t good enough to satisfy, so I

thought it out, and concluded that at this scale even

steel is fairly soft if it’s thin enough. For

decent stiffness you want either thicker sections, box

beams, or even Buckminster-Fuller-Style Octet Trusses,

if you have the materials and the patience it would take

to build them. I decided on box beams, for simplicity

and ease of construction. (That involved the hobby shop

in this project — only a few hardware stores carry

the rectangular-cross-section brass tubing that I used.)

It also seemed like a good idea to have the screws go

through the stator and to put the pivot point on the

rider. I am calling this improvement Rev 3B rather than

V4, as I could have tweaked any of the versions this

way, and also because I built it by reworking an

existing mount instead of starting afresh.

Swapping the two pieces was easy. I did drill out the

holes in the backup plate for the stator, because they

were just a bit too small for the heads of the screws to

fit through, but this hardly counts, because you could

do it with a file in a few minutes. Here are the

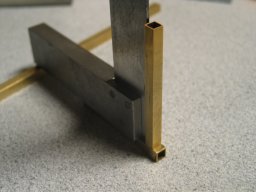

constructed boxes:

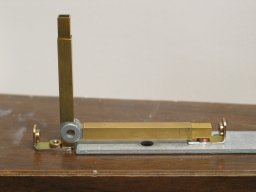

Here is the mount on a base, before I built and

installed the mirror cell:

The mirror cell for this mount consists of 3 main

pieces, as that was about the easiest thing I could put

together from what I had on hand. 2 of the pieces are a

faucet aerator and adapter, as pictured above; the third

is another adapter. I also used a metal washer or two,

some o-rings, and a neoprene washer. These are to hold

the mirror in place and prevent it from contacting

metal, which might chip it.

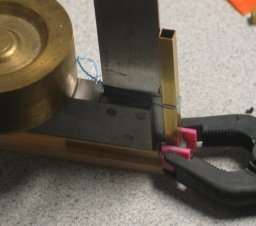

Here are photos of the cell being glued into place,

with both adapters on & the aerator body removed

(for balance), and of the completed mount:

I have tested this mount, and as far as I’m

concerned, it is a decent and usable design. As with the

earlier versions, it can be built entirely from parts

and materials that are available at hardware stores and

hobby shops, though some of you may have to go to a

bicycle store or some other odd place for small steel

balls; and it can be built with nothing more than a

jeweler’s saw, a file or two, a hobby knife, and

some sandpaper, though I will admit that it is rather

more convenient if you can drill a few holes fairly

accurately. (You do need to drill at least one hole in

order to glue the balls on the ends of the adjustment

screws, but it should be possible to build a jig to do

that from a few pieces of paper, which would eliminate

all need for drilling. I may write that method up and

post it here at some point, if I have time.)

Here, in case anyone wants it, is an “X”

(cross-eye) mode pseudostereo (that is, I took the two

photos separately) macrophoto:

...And now, on to the next item in this set.

(23 August, 2007)

In connection with one of my projects, I find that I

need some translation stages. (I need to position a

pinhole for a spatial filter, and I need to position one

or two iris diaphragms.) In order to fill these needs I

have designed a translation stage that can be built for

one or more axes, uses only materials that are available

at hobby shops and hardware stores, and does not require

any machine tools beyond a Dremel® or other rotary

tool. You will, however, need a jeweler’s saw

or something similar; a very small bandsaw might do.

Here is the basic structure I am making use of; I

bought these at a local hobby shop:

In each case, what we have is a tube that fits very

nicely over either a rod or another tube. With a square

cross-section, rotation around the axis is not much of a

problem: the fit is fairly decent. Still, if you need

precision, the square configuration probably has more

wiggle-room that you are going to be comfortable with.

In order to use the round cross-section you must resort

to low cunning, and use them in pairs. The easiest way

is to glue the two sleeves together; they have to be

very nicely parallel, but that should be fairly easy to

arrange. Another advantage of the circular cross-section

is that the rods, especially in pairs, are considerably

stiffer than hollow tubes. A third advantage of doing

things in pairs is that you can push (or pull) the rods

apart a little at their ends, which should eliminate

most of the runout/wobble.

You do not have to use the concentric structures

I’ve shown above; it is perfectly reasonable to

use pieces of angle iron (or of aluminum angle

extrusion) that ride on the rods. (I would, though, use

stainless steel rods rather than any type of thin-wall

tubing for this version.) You will, of course, have to

make sure the riders are held onto the rods on any axes

where gravity won’t hold them on for you. It is

also probably a good idea to be sure that rods and

riders are all as straight as possible.

Here is a rude ASCII-pic cross-section. The /\

structures with the little ^ “hats”

are the angle pieces; the Os are the rods or

tubes.

(The hats should actually be integral with the /\

structures, but of course ASCII is not conducive to

the accurate representation of detail.)

You could put a “floor” between the two

riders to make it easy to mount things on them, just as

you can with the concentric structure:

Back to the main flow, and to actual construction...

My initial needs are not stringent, and for a first

prototype I am going to make a 2-axis stage using the

uppermost pair of square tubes from the photo, above.

(The outer sleeve is 1/4" square and the inner is 7/32",

which should give me reasonable strength and stiffness.)

I would like to have perhaps half an inch of travel or a

little less, so I am making the sleeves 2" long and the

shafts 2.5" long.

It is rather important to ensure that the second axis is

orthogonal to the first one. Fortunately, I have a small

machinist’s square here. If you don’t have a

square you can acquire one, or find something that has a

reasonably accurate right angle. For most purposes we

are not talking about microradians.

Here is a photo of the setup, with the second-axis shaft

in position to be glued onto the first-axis sleeve:

Once I have the two axes connected, I need to be able to

adjust their positions. Zimmerman’s (mentioned

above, in the section about the mirror mount) carries

M3-0.50 screws and nuts, which suit this application;

0.50 mm is just under 0.020 inch, and that is probably

adequate precision for positioning an iris diaphragm.

When I build the 3-axis stage for the pinhole of the

spatial filter, however, I will need either micrometer

heads, the differential screw arrangement that is

further down this page, or both. (I think I have only

two small mike heads, which leaves me using a

differential screw for the third axis.)

To return to the prototype: rather than letting the

first-axis screw push on the base of the second-axis

shaft, which would reduce the usable travel of the

second axis, I am thinking about gluing a small stop

into place on the first-axis sleeve.

(Evening of 24 August, 2007)

I have checked to see where I need the iris on the

laser, and I have epoxied the shaft of axis 2 onto

the rider of axis 1, using two small washers as

gussets. Here are two slightly blurry (sorry) photos

of the gluing setup, showing the square I’m

using as a reference

(The little spring clamp is holding the washers in place.)

Notice that the square is generating 2 axes of

reference. The shaft is in contact with it all

the way up, which is one axis; in addition, I

centered the square on the bottom shaft as well

as I could by eye, and then I centered the top of

the vertical shaft against the square as well as

I could. (Again, my needs here are not terribly

stringent; if they were, I would have acquired

at least one more square, and possibly two.)

I have also purchased some small springs, to use as

tensioners; still thinking about how to attach those,

how to mount the adjustment screws, and how to mount

the stage on its base. I will have to put the base on

a pedestal for this laser, but that’s a separate

issue.

I need angle brackets to hold various pieces of this

stage. Here is the glued assembly for the two axes

(with riders on the shafts), as well as some possible

angle brackets and sources:

As you can see, old computer parts turn out to be

valuable in new ways. Here is the first foot being

glued onto the stage:

Here is the control mechanism for the Y axis:

(I epoxied a plate with some holes in it on top of the

shaft, and attached the relevant items. I put an L on

the traveller, with a bar behind it for the springs to

attach to. I also added a stop nut on the adjustment

screw, because if I try to push the axis past its travel

limit I will detach the plate from the end of the shaft,

which is a Bozo No-No and is severely deprecated.)

Here is the completed stage. As you can see, I did the

control for the X axis slightly differently; but the

principle is the same. (I will probably add a stop nut

on this axis to match the one on the Y axis, though

because of the construction it isn’t really

necessary.)

This device is now ready to go into the laser. If

and when I get any results worth reporting, I will

add a link to the relevant page.

Two further notions:

1) You can always acquire a single axis by disassembling

a dead CD-ROM or CD/DVD player. The laser head rides on

rails, at least in the players that I find inside

computers. Here is a photo of an assembly that I took

out of an ancient Mitsumi ROM reader; it still has the

disk rotation motor on it, but that was easy to remove.

The laser and other irrelevant parts of the head should

also be easy to get rid of, if you don’t just

decide to ignore them.

This has the advantage of giving you an actuator, though

you may choose not to use it. You could fairly easily

build a multi-axis stage from these if you don’t

need it to be particularly compact. Alternatively, you

could use one of them as the lowest level of a 2- or

3-axis stage.

2) A chap named Brian Manning has made his own version

of the ruling engine that appeared in the Amateur

Scientist column of Scientific American in April, 1975.

His page about it is a gem.

(25 May, 2007)

It turns out that there is a nifty way to make a

differential screw — you butt two screws together

(with a compliant coupling, unless you are abundantly

certain that they are rather precisely collinear and

well aligned with whatever you are using them to move),

and use a fixed nut on one & a travelling nut on the

other. You can think of the screws as being there

primarily to connect the nuts together; the fixed nut is

the reference, and the other is the driver. In practice,

it’s not quite as simple as it sounds; but it is

nonetheless a remarkably easy way to permit relatively

fine adjustments. (We are not talking single wavelengths

of light here. That takes slightly more advanced

techniques, or really careful construction, and

good temperature control.)

I desperately wish I’d made this up, because it is

so ripping brilliant, but I didn’t; someone

told me about it, perhaps a decade ago. Somebody almost

certainly has (or had — probably long expired) a

patent on it.

[I’m going to assume, for the purposes of this

explanation, that the coarse screw rides in the fixed

nut, so that the final motion is “forward”

when you rotate the coarse screw clockwise. There is,

however, absolutely no reason why you would have to do

it that way if you didn’t want to.]

When you rotate the coarse screw, it moves in the

reference nut. That pushes (or pulls) and rotates

the fine screw, which thus pulls (or pushes) the

travelling nut almost back to where it was before you

rotated the screws. How much of a change in position you

get depends on the ratio between the thread pitches. If

you have, for example, M5-1.0 and 10-24, you’re

looking at about 1.4 mm for 24 turns, which is quite

decent. If you can make everything out of the same

material, and if you can control the temperature

in the room precisely, you may want to try M5-0.8

(fine pitch) and 10-32, which gives you 0.2 mm travel

for 32 turns of the 10-32 screw. (It’s 0.8 mm/turn

vs 0.79375 mm/turn.)

I don’t need anything like that kind of precision

for my current application (positioning the ends of the

electrodes of a TEA nitrogen laser), so I went with a

much bigger difference. My coarser screw is 10-24 NC and

the finer one is 10-32 NF. The 10-24 moves forward 1" if

I rotate it through 24 turns, and the 10-32 pulls the

travelling nut backward 24/32", which = 3/4", so the

pushrod I’m using as an actuator ends up going

forward by 1/4".

That is, 1 turn gives me a little over 10 mils, and one

“hour” (if you think of the thing in terms

of a clock) gets me just under 1 mil.

Here are two preliminary photos, with the electrode not

yet attached to the pushrod:

You’ll notice that the fixed and travelling nuts

are composed of two hexnuts each. This is a crude

anti-backlash mechanism. To do it right, you actually

have to make an extra doubled nut & run it up and

down the screw a few times with some extremely fine

abrasive, so it takes out all of the irregularities in

the threads. Then you set that nut aside, remove

ALL of the abrasive from the screw, and put on

the real anti-backlash nut. I’m not going to

bother, and I’m not going to tighten up the

anti-backlash very much — I just want to take out

a little of the slop.

Speaking of slop, this version is probably not really

accurate for anything as tiny as 1 mil, because there is

only RTV [in this case, aquarium caulk] between the nuts

I’ve glued to the ends of the screws to provide

sufficient area for good coupling; in order to get

enough stiffness for real accuracy, I would have to make

sure they were always in metal-to-metal contact. (Care

to think up a nice simple way to achieve that and still

have a compliant coupling that allows for [or prevents]

all of the possible misalignments? Definitely a fun

project.) OTOH, once the RTV stiffens up fully, it

should certainly be good enough for folk music.

It is not trivial to figure out the details on one of

these, and I have probably made some mistakes here, as

this is really the first time I’ve tried to build

one; but I’m sure that a bit of hands-on

experience will get me where I want to go. I don’t

really need even as much as 1/4" of travel for the laser

I’m working on right now, which helps.

(24 August, 2007)

I noticed that

The Surplus Shed

has some inexpensive diffraction gratings, so I bought

one and used it to build a little hand-held spectroscope

out of Schedule 40 PVC plumbing pipe and fittings. Here

are two photos, showing the way I constructed the ends:

I have angled the slit, so that one end is a bit wider

than the other. I hope this will let me see some of the

Fraunhofer absorption lines in the spectrum of the sun.

Note, btw, the fact that the slit end consists of two

threaded fittings. The one that the slit is mounted on

screws onto the one that is glued to the main tube.

Doing it this way lets me line up the slit with the

grating easily. (It also lets me replace the slit with

an adjustable one, should I ever decide to do so.) The

two pieces of flat plastic under the razorblades are

there for two reasons: first, to exclude extraneous

light that would otherwise go around the back edges of

the blades. Second, the blades are not actually wide

enough to reach the edge of the fitting, so I had to

support them. You can also see a small piece of wood at

the edge, where there is a space between the two flat

pieces. Again, it is there to exclude extraneous light.

The other end may be slightly unusual; the hand

spectroscope I had when I was a kid was simpler —

it had both ends cut off square, so its grating was

parallel to its slit, and there was nothing past the

grating at the eye end. I set the grating of this one at

the angle that gave me the brightest spectra, and I

added the extra tube to prevent other lights from

interfering with my view of the grating. (Since this

picture was taken I have changed the angle at the

end slightly, so that if I hold the filter on the

front of the camera up against the tube, the lens

points more or less directly at the spectrum I’m

trying to photograph.)

Here are a few spectra. First, a halogen bulb produces

the expectable continuum, which may let you get a

sense of the bands that the camera’s sensor

is picking up. Then the discharge inside a HeNe

laser. Third, a compact fluorescent bulb; and

finally a spectrum of one of the HID headlights

of my car:

(The middle two are somewhat underexposed;

the left edge of the HID headlight one is grossly

overexposed.)

The grating is definitely not the greatest I’ve

ever seen, but it didn’t cost very much, and it

clearly works. (Note, added on 15 September, 2007: I

have purchased what I hope is a better grating on eBay,

and if it works out well I will post a revision here.)

The new grating does, indeed, work pretty well, but

it will require two photographs to cover the visible

spectrum until and unless I shorten the sighting tube.

This is because the grating, a rectangle that is about

twice as long as it is wide, is ruled with the lines

going the wrong way. At some point I may acquire a

better one, but this one serves reasonably well for

just looking at the spectra of reasonably bright

sources.

(09 January, 2011, ff)

I have been building some gas lasers, or trying to, and

as part of that effort I have had some difficulty

achieving a sufficiently good vacuum. I am fairly sure

that the roughing pump I’m using is good enough,

but I found that I couldn’t even get the laser

head down to 1 Torr.

Part of this appears to be a materials issue: silicone

rubber caulk appears to continue to outgas for quite

some time after it is apparently fully cured, or perhaps

it allows some air to diffuse through; either way, I

think that it is not particularly suitable for use in

vacuum systems, even crude ones.

There is a special epoxy called Torr-Seal, which is good

down to about 1.0X10-9 Torr; it is rather

expensive, but it does work. If you look on the Web, you

will find claims that Loctite’s Hysol 1C (which is

far less expensive) is very similar, but I don’t

see any actual performance test results. My current

conjecture is that just about any properly-mixed epoxy

should be good down to better than 1 micron

(10-3 Torr), and I am guessing that J-B Weld,

which contains fillers of some sort, may be slightly

better than most.

Then there is the question of teflon pipe tape. How good

is it? It certainly appears to be adequate in the

low-milliTorr range, which is good enough for me, at

least for now. I am, though, curious about whether it

can be used at lower pressures.

In any case,

here is a page on my rebuild of the manifold

for this setup.

To the Joss Research Institute Website

To my current research homepage

My email address is a@b.com, where a is my first name

(just jon, only 3 letters, no “h”), and b is joss.

My phone number is +1 240 604 4495.

Last modified: Wed May 10 15:03:28 EDT 2017

Version 3:

It’s Time to Rethink (Again)

Sidebar: A Brief Note about HeNe Lasers

Revisionist Tendencies

A Simple Translation Stage

Sidebar: A Slightly Simpler Alternative

^ ^

/O\/O\

^ ^

/O\___/O\

A Simple Differential Screw

A Simple Hand Spectroscope

Improving a Small Vacuum System

the Joss Research Institute

Contact Information: