I: The Copper Quadrupole

(2011.0226)

For the first version of this laser I built a quadrupole from copper tubing. For various reasons it was not successful, but I did learn quite a bit from it. This time I am using glass (rather than plastic) for the insulators on the sides of the structure, and (as mentioned above) epoxy rather than RTV. It also became clear while I was working with the earlier machine that there were some issues with the structure as it was designed and built; for example, the discharge confined itself to the bore only under fairly restricted circumstances. It should (we hope) be relatively easy to prevent arcs at the ends of the quadrupole, by putting a conductor in close proximity; this is the same method I am using to avoid arcs between the tubes that serve as poles in the structure, and relates to the Paschen curve (as mentioned on page 016a).

Here is a preliminary photo of one pair of electrodes at an early construction stage:

The small glass tubes that I’m using as insulators are not easy to see in this photo; they are melting-point capillaries that I acquired on eBay. (Hematocrit capillaries would also work.) If you look carefully, though, you can see the ABS spacer between the two copper tubes. It holds them 0.3 mm apart for initial assembly.

I have set up both pairs of tubes with dots of J-B Weld to hold the glass tubes in place, but I have not applied any more epoxy to them yet. I will probably do that before I attempt to assemble them into a quadrupole structure, as it seems much easier that way.

Meanwhile, I am also rebuilding the vacuum manifold on the roughing system that I’m using with these lasers; but that is peripheral to this effort, and is discussed on a different page.

(2011.0227)

I have applied transparent epoxy to one side of each pair. Here is a detail of one end:

(The epoxy is on the right half of each pair. It is not easy to see.)

(2011.0228, afternoon)

Both pairs now have epoxy down both sides of the capillary tubes. I hope to assemble them into a quadrupole structure this evening. I’m a bit concerned about drilling holes into the sides of the tubes, and I think perhaps that will wait until the quadrupole is built and strengthened. (I want to block off the ends of all four tubes, and have vacuum only down the bore of the laser.)

Once I have the quadrupole built, I expect to use TO-220 ceramic insulators as endpieces. I have not yet decided whether to attach end fittings directly to the endpieces or interpose short pieces of glass tubing, but at the moment I am leaning toward direct attach.

(Later, that evening)

I spaced the halves of the quadrupole 0.3 mm apart with a wider (~6 mm) strip of ABS plastic, and I have put the third set of glass tubes on with small dabs of J-B Weld. When the J-B has had time to cure, I will probably add epoxy as I did with the halves of the quadrupole, to strengthen the structure before I turn it upside down and apply the final set of tubes.

(2011.0308, early AM)

Some epoxy got between two of the tubes, and I have ordered a set of very thin circular sawblades, in hopes that I can remove some of it. That should let me operate this quadrupole. In the worst case I can still separate the two pairs of tubes, after which either I should be able to remove most of the epoxy that is in the wrong location and put the two pairs back together again, or just build another pair and reconstruct the quadrupole using it.

In the meanwhile, I have acquired a pair of end fittings, and I continue to think about relevant issues. One problem with this design, just as with the string-of-beads design in the first section on this page, is differential thermal expansion. I cannot permit either head to get too hot during operation.

(2011.0326, afternoon)

Here is a preliminary look at the ends of this quadrupole and the stainless steel one, with a rule so you can get a good sense of the overall sizes and the bore sizes:

I still have to fill the ends of all the tubes, and then cut small holes in the copper ones. (The stainless steel tubes already have laser-cut holes in them.)

(2011.0304, afternoon)

I have been interrupted by a conference, but I did manage to fill the ends of the tubes with epoxy. I still need to drill a hole in each of the copper tubes.

(2011.0615)

Some time has passed. I have made endpieces for both tubes, and epoxied them in position. Here is one of them, being glued to the copper quadrupole:

I was fortunate here; toothpicks were about the right size to serve as positioners. Both endplates are now attached, and I have acquired brass compression tees to serve as gas inlet and outlet and to hold mirror mounts.

[[More as it transpires...]]

My rationale here is that He-I2 operates at

relatively high pressures (several Torr), emits several

visible lines, and lases well in hollow-cathode

structures that are a few mm across. It may even be

possible to use mirrors from a HeNe laser, as the best

line in the visible spectrum seems to be at 612.7

nm. That’s a bit more orange than the common 632.8

nm HeNe line, but still fairly close, and I hope that

the mirrors will have good reflectivity (though it is

possible that I will get beams from both ends of the

device, assuming it lases at all).

If I can build a structure that is decently leakproof,

I should be able to lase a helium-argon mixture in it;

this version of the argon laser emits at 476.5 nm, a

pleasant blue color. This, however, involves only a few

milliTorr of argon, and adjustment is likely to be

rather tweaky.

.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.

(Earlier note: 09 January, 2011, morning)

Jarrod Kinsey has pointed out one of Dr. Mark Csele’s

pages, on which he describes running a small CW argon

laser in pulsed mode. For some reason, he finds that he

must apply remarkably long electrical pulses (more than

10 μsec) in order to get any lasing. I was using

much shorter pulses with an earlier version of this

laser, and did not succeed; this may help explain why.

.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.-=^=-.

I will be introducing the iodine (or argon) along with

the helium, so I don’t want the wall material to

sputter into the discharge or to react with iodine.

Stainless steel seems to be a reasonable material in

both regards, and it is readily available, so I have

used it here. (See the photo at the end of the previous

section.) I bought the tubes from

The Electronic Goldmine;

I think they cost all of 99 cents each, plus shipping.

I got 6 of them, knowing that I would probably have

trouble with at least one of the pairs (which, in fact,

I did — I didn’t align the tubes well enough

when I glued the insulators to them).

The Paschen relationship for helium suggests that the

highest viable pressure for a structure that amounts to

a tube with inside diameter of ~2.5 mm is a few Torr.

That is somewhat low for helium-iodine, which has been

found in at least one study to operate best at about 13

or 13.5 Torr; but this design may be viable anyway

— at least one published study has used a

comparable design at pressures of more than 10 Torr.

(2011.0326, afternoon)

See the end of the previous section for a view of the

end of the stainless steel quadrupole. This quad has a

problem: in one area there is epoxy between the tubes.

It does not obstruct any of the bore, and if I am very

lucky it will not have any effect. If I am not so

lucky, a discharge will form across the epoxy surface

instead of inside the bore; but we’ll cross that

bridge if and when it burns under us. (If such a discharge

did form, it would probably carbonize the epoxy and

short-circuit the tube. It’s a good thing that

these tubes are inexpensive.)

(2011.0404, afternoon)

I have filled the ends of the tubes with epoxy. The

next step is to put end plates on the structure. Then

I need to add gas ports and either mirror mounts or

Brewster-angle windows, or possibly plain AR-coated

windows.

(2011.0615, late afternoon)

This quadrupole went together reasonably well, and is

now almost complete. Here it is during construction; I

had just put the two halves of this quad together, and

you can probably see the styrene spacer in the middle.

The outer insulators, which are sets of melting-point

capillary tubes, are in place, but I have not yet

applied the epoxy around them that prevents vacuum

leaks.

Here it is at a later stage, with one of the endplates

being attached to it:

Note the pieces of styrene ribbon being used as spacers.

It is easy for these to get stuck in the epoxy, but once

the end positions are established it is possible to take

the plate off, remove the styrene, and epoxy the plate

back on without the spacers — the existing epoxy

serves to maintain the spacing. (Yes, I know this

because I had to do it. The epoxy wicks into the gaps

very nicely when it is freshly mixed...) Notice also the

small machine screw; the hole is not in the middle of

the plate, and it kept tipping until I weighted it.

I have both ends attached now, and I need to find a pair

of stainless steel fittings to serve as the gas inlet

and outlet (and to hold mirror mounts).

[More as it transpires...]

My initial feeling about the active structure of this

laser is that I want to build something that has a

more-or-less-circular bore. Obviously, the structures I

built above, from round tubes, fail to meet this

criterion. There are two obvious ways to achieve a

circular bore, the first of which is to use a

“string of beads” structure like the one on

the next page, made of copper and brass for a copper

vapor laser, or of stainless steel for a He-I2

or He-Ar laser. The other is tweakier and more

difficult, but should have significantly better

performance. It is achieved by clamping 4 rods together

and drilling a 2.5-mm, 3-mm, or even 3.125-mm hole down

the line where they join. I would have to do this in

sections that are quite short, because I don’t

have any special drills, but that isn’t too

terrible. I debate whether to space the rods before or

after I drill them, and I think I would most likely

clamp them with the spacers in place. This effectively

provides a centerpunch at the point where they come

together, and gives me a bore that really is more or

less a circle. (If I were to drill first and then space,

the bore would be slightly off-round.)

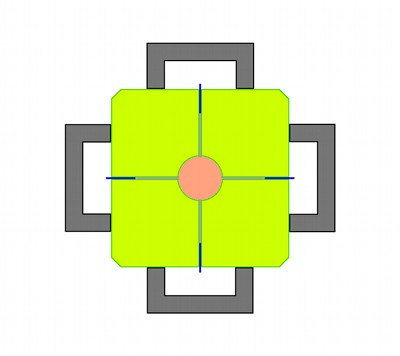

Here is a rough diagram, not to scale. The yellow-green

areas with green borders are stainless steel; the pale

pinkish-orange circle is the bore; the blue lines are

spacer/insulators. (I don’t have anything fancy,

so unless I can find some nice glass or ceramic ribbon

or maybe circuitboard that is about 0.3 mm thick, I will

probably use ABS plastic from the hobby shop, and try to

keep it well away from the discharge.) In addition to

providing insulation, these are somewhat structural; but

I strongly suspect that other external structural

members will be required, as the spacings between the

pieces must be maintained firmly. I have shown these in

gray with black borders; they should be regarded as

schematic rather than directly representative, as I

don’t know what they would (or will) look like

if I actually build a design of this type. Note that

the only areas that are under vacuum (other than the

bore, which is the salmon-colored circle in the middle)

are the thin (0.3 mm) gaps that extend out from the bore

to the spacers. They are indicated in mauve.

(02 January, 2011, early afternoon)

Frankly, this would be seriously nontrivial to

construct, and I have diverged in order to build

string-of-beads copper ion laser (see the next page) and

the quadrupoles described earlier on this page. Despite

being difficult, though, this design is attractive

specifically because the bore is circular. That

apparently enhances electron oscillation in the

discharge (which gives the laser its desirable

characteristics), and I suspect that it also has a

greater tendency to produce a

TEM00 mode

structure.

[[More as it transpires.]]

(02 January, 2011, afternoon, ff)

Here are some useful abstracts. In some cases I have

found and read the article at the University library or

online; in others I am probably going by what I have

found in the abstract, as that was enough information to

get me started.

Longitudinal hollow cathode copper ion laser:

optimization of excitation and geometry (Proceedings

Paper)

Abstract

It is demonstrated experimentally that for copper ion

lines laser excitation in a longitudinal hollow cathode

discharge (HCD) an optimum current density (approximately

1 A/cm2) exists. Above this value a saturation and even

decrease of the laser power is observed. Due to the

axial inhomogeneity of the longitudinal discharge the

possibility to increase the laser power by increasing

the cathode length is also limited. To determine the

proper cathode length for a sputtering copper ion laser,

the axial current and spectral lines intensity

distribution at conditions typical for laser oscillation

are measured, showing a maximum at the anode ends of the

cathode. Numerical modeling for exactly the same

discharge conditions and tube design is also

performed. The results are compared with the measured

data and reasonable agreement is reached. Based on the

results of the experiments and calculations we have

demonstrated that the most efficient laser oscillation

is achieved when the laser active volume comprises a

series of anodes and cathodes, each cathode with a

length of approximately 1 x 2 cm.

[Note: the “x” between 1 and 2 in that last

sentence is actually a “divided by” sign.

When I find the correct HTML code, I will restore it.

Unfortunately, I am not entirely sure what they meant

by it.]

The conclusions here put a severe limit on the performance

I can expect to get from my “string of beads”

sectional tube, with alternating anodes and cathodes; but

at least it appears that such a tube can be a viable laser.

Comparison of Cu-II 781 nm Lasers Using High-Voltage

Hollow-Cathode and Hollow-Anode-Cathode Discharges

Abstract

Voltage-current characteristics and the Cu-II 780.8 nm

laser performances are described for a novel segmented

hollow cathode and for three- and four-slot

hollow-anode-cathode (HAC) tubes. Each of these operate[s]

at a higher voltage and with higher slope resistance than

a conventional hollow cathode, and [they] produce improved

laser performance. The best laser performance is obtained

with the segmented tube. The application of a longitudinal

magnetic field raises the discharge voltage and enhances

the laser performance for the segmented tube, and raises

the voltage for the four-slot HAC tube. The magnetic field

lowers the voltage and reduces the laser performance with

the three-slot HAC tube. The voltage effects are attributed

to the deflection of the fast electrons by the magnetic

field strength, and represent experimental evidence for

the oscillation of electrons in a hollow-cathode discharge.

Note: I have performed minor editing on this, adding a

few commas and the items enclosed in square brackets.

This is a crucially important paper, and is probably

available on the Web in PDF format.

Dependence of the infrared output power of a hollow

cathode Cu+ laser on He and Ar pressures

Abstract

The dependence of the infrared laser power produced by a

hollow cathode copper ion laser on the He and Ar

pressure is reported. An argon partial pressure of 1

mbar is found to be optimum and nearly independent of

the helium partial pressure and discharge current. The

optimum He pressure is about 25 mbar, dependent on the

discharge current. A simple rate equation model is given

and compared to the experimental results.

Parametric study of a high-voltage hollow-cathode infrared

copper-ion laser

Abstract

A new, segmented-electrode, high-voltage, hollow-cathode, Cu II

laser, operating on the 780.8 and 782.5 nm transitions, is

studied. Parametric measurements are presented for the discharge

voltage, the spatially averaged copper-atom concentration and,

for the two transitions, the small-signal gain coefficient, the

laser threshold current and the laser output power. The

dependence of the laser output power on the active length, the

buffer-gas pressure and the transmission of the output coupler is

modelled using equations for a low-loss, homogeneously broadened,

standing-wave laser. For the 780.8 nm line, the lowest threshold

current is 0.19 A for a 5 cm active length and a 0.1%

transmission output coupler, and the maximum output power is 58

mW for a 3 A discharge current, a 7.5 cm active length and a 2%

transmission output coupler. This performance exceeds that of

conventional hollow-cathode lasers on the same transition, the

improvement being attributed to the increased operating voltage,

which gives a more efficient pumping discharge by simultaneously

raising the ground-state copper-atom concentration (through the

increased sputtering yield of ions bombarding the cathode) and

increasing the efficiency of ionization.

Dependence of Gain and Laser Power for Cu-II 780.8-nm Transition

on the Diameter of a Segmented Hollow Cathode Discharge

Abstract

The dependence of laser performance and discharge characteristics

on the diameter of a segmented hollow cathode discharge for the

Cu II 780.8 nm transition is presented. This transition has a

special importance since its upper level is common to potential

CW VUV laser transitions (150-170 nm). Laser tubes with internal

diameters of 2, 3, 4, and 5 mm were investigated. Decreasing the

diameter resulted in an increased gain for a given current (up to

100 %/m in the 2-mm diameter, 5-cm-long tube at 1-A current). The

highest output power was obtained from the large-diameter

tubes (20 mW from a 5-cm-long, 5-mm-diameter tube at 2-A current,

without optimizing the output coupler). This work is a part of a

series of investigations aimed at the optimization of the

segmented hollow cathode discharge, which has already been found

to be the most efficient type of discharge for cathode sputtered

metal ion lasers.

[Note: This is a very helpful paper. It may be available on the Web,

and is well worth reading.]

Back to the first quadrupole page

Back to the first page of this set

To the Joss Research Institute Website

To my current research homepage

My email address is a@b.com, where a is my first name

(just jon, only 3 letters, no “h”), and b is joss.

My phone number is +1 240 604 4495.

Last modified: Wed May 10 15:12:36 EDT 2017

II: Stainless Steel (He-I2 and He-Ar)

III: A More Formal Quadrupole Design

References:

Diana B. Mihailova; Margarita G. Grozeva; Annemie

Bogaerts; R. H. Gijbels; Nikola V. Sabotinov

Proceedings Vol. 5226, 12th International School on

Quantum Electronics: Laser Physics and Applications,

Peter A. Atanasov; Alexander A. Serafetinides; Ivan

N. Kolev, Editors. (4 November 2003) pp 49-53

K. A. Peard, Z. Donko, K. Rozsa, L. Szalai, and R. C. Tobin

IEEE Journal of Quantum Electronics, V30N9 (Sep 1994) pp 2157-2165

Eichler, H. J. Wittwer, W.

[Optisches Institut, Technische Universitä, Berlin, Germany]

Journal of Applied Physics, V51N1 (Jan 1980) pp 80-83

K A Peard, K Rozsa and R C Tobin

Journal of Physics D: Applied Physics, V27N2 (?Feb? 1994) p 219

Szalai, L. Donko, Z. Rozsa, K. Tobin, R.C.

IEEE Journal of Quantum Electronics, V31N8 (Aug 1995) pp 1549 - 1553

the Joss Research Institute

Contact Information: